Recent updates to the platform have improved accessibility for users.

Sealing Sense

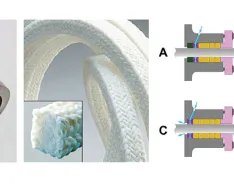

Reducing friction while maintaining effective sealing is often critical.

Lessons to be learned from the 1988 Piper Alpha disaster.

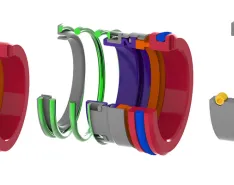

Exploring the fundamental components of mechanical seals and comparing different seal types.

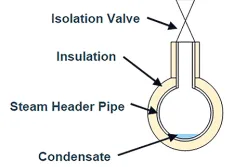

How to address jumping pipes without causing further damage.

What to consider when selecting the proper rubber expansion joint.

A look at the past and potential future of mechanical seals.

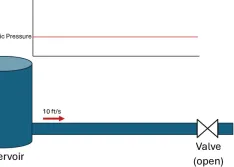

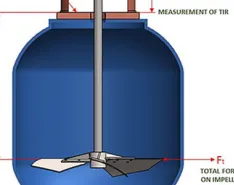

Advantages, operational needs and tips for optimal operation.

Comprehensive training is imperative to ensuring quality and safety.

Understand how ratings and testing of this equipment makes a difference.

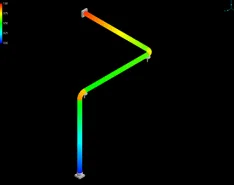

Simulation software can be a beneficial tool when used in incorporating rubber joints.

Considerations for starting a successful program in your facility.

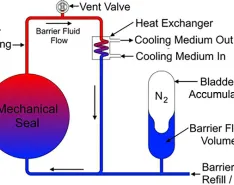

These seals offer operational cost savings and simplicity in support systems.

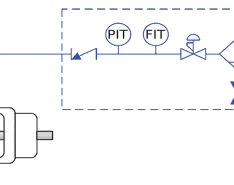

How flow meters, packing and other equipment can help minimize the amount of water needed.

An introduction to expansion joints and their uses in food and beverage applications.

In this report, the Fluid Sealing Association explains that not all chemicals in this category are dangerous, namely polytetrafluoroethylene.

A look at the steps taken to ensure food and beverage safety.

Hydropad technology lowers face operating temperatures and improves efficiency.

Select the right sealing solution for a specific application.

This component keeps equipment running efficiently.

Finding the right seal depends on the equipment and application.

The newest generation of split seals offers cost savings, self-alignment and eliminates need for equipment disassembly.