Over the last two years, 16 renewable diesel plants have become operational in the United States. Of these, 13 were conversions from traditional petroleum refineries. In total, these plants can produce more than 2.6 billion gallons of renewable diesel each year.1

The trend of converting traditional petroleum refineries to renewable diesel production continues to gain momentum, driven in part by government policies and incentives. The pumps and compressors that refine fuels in traditional plants must be updated to handle the different feedstocks used in renewable refineries. These updates require new parts and a host of other upgrades.

A Closer Look at Renewable Diesel

Approximately 50% of crude oil used around the globe is refined into transportation fuels, which create greenhouse gas emissions. Biomass is a cleaner energy source that can be mixed with crude oil and converted into liquid transportation fuels. Like ethanol that is mixed with crude to make unleaded gasoline, a range of renewable materials can be used as feedstocks for diesel. These include plant-derived oils such as soybean oil, palm oil or other green feedstocks.

The refining process for renewable diesel is similar to traditional refining. Renewable feedstocks are mixed with traditional crude oil and hydrogen, and they are pumped at high pressures into multistage catalytic reactors. Throughout the process, byproducts (such as propane and naphtha) are separated, and a wide range of properties are adjusted to meet a refiner’s specifications.

The viscosities of the feedstocks used in renewable diesel refining differ from traditional refining feedstocks, so equipment must operate at different flows and pressures. The pumps most commonly used in refining include American Petroleum Institute (API) single-stage, integrally-geared pumps and multistage pumps.

How can operators ensure that pumps are optimized to run at peak efficiency? It starts with sizing the pump properly for the required task. This is accomplished by advanced analytics and computer-tailored hydraulics that place the best efficiency point (BEP) at or slightly below the rated point. This enables smaller drive sizes to be utilized, which can still deliver the required output while saving energy.

For refiners making the shift to renewable diesel, pumps and compressors handling renewable diesel feedstocks should be rerated to keep them operating within the API limits (ideally between 80% and 100% of BEP). Rotating equipment operating above or below rated flow can result in cavitation, seal failures, high vibration and motor overloads.

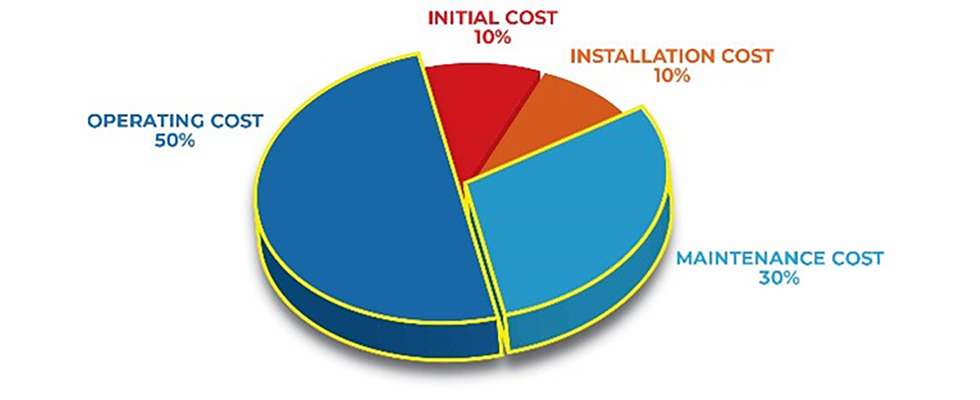

Pump or compressor failures of any kind result in poor mean time between repair (MTBR), plant downtime and increased maintenance costs. Preventing this domino effect is critical because maintenance and operational costs can make up as much as 80% of the total life cycle costs.

The Shift to Renewable Diesel

Enhancements in manufacturing, combined with user feedback from operators in refineries, have identified the following 10 areas for optimizing pump and compressor performance, extending maintenance intervals and reducing total costs of ownership:

- Pump and compressor upgrades: Outdated compressors/pumps in the field can be upgraded with the latest technology without changing out the major components (such as the casing, housings and foundation).

- Rerates: If process conditions change and operators identify units not running near BEP, then hydraulic rerates are required to achieve these new requirements. Efficiency improvements are achievable without requiring a new motor, footprint or piping. Some rerates can provide 30% additional head with 10% power savings.

- Seal replacements: New seal technology extends seal life and improves seal performance. Modifications to seal housings can improve fluid flow-through and remove high-point vapor pockets, which improves seal life.

- Cartridge seal upgrades (if applicable): Self-contained cartridge seals include a shaft sleeve, seal and gland plate. They are fitted onto the pump shaft as a single assembly, to facilitate error-free replacements for pump shaft seals.

- Inboard and outboard bearings: The latest generation of bearings technology offers better rotor stability over a wider operating range. This can reduce vibration, which helps to extend seal longevity.

- Bearing frame upgrades: Power-end replacements enhance reliability and ensure compliance with current API 610 requirements.

- Gearbox conversion kits: These deliver up to 10 design improvements via an interchangeable, bolt-on package that delivers an estimated minimum 5-year mean time between maintenance (MTBM). Gearbox exchanges provide better bearing life, and they include stronger gear sets that facilitate higher load levels.

- Compressor inlet guide vanes (IGVs): These are a series of blades arranged at the inlet of a compressor that “pre-swirl” the gas flow entering the impeller. IGVs increase compressor turndown while reducing the amount of work needed from the main driver. This results in improvements in efficiency and lower power consumption.

- High efficiency compressor impellers: Recent impeller design improvements enable compressors to produce the same amount of flow, utilizing up to 20% less power than previous designs.

- Instrumentation: Updated vibration and temperature sensors give operators peace of mind and reduce the cost of repairs by identifying issues before they become catastrophic failures.

These upgrades cover almost 90% of the maintenance requirements for rotating equipment. Upgrading key components can add decades of service life. Upgrades also eliminate the cost of installing a new pump or compressor, which in refineries involves highly customized processes requiring unique foundations, complex piping runs and teams of welders, concrete workers and crane operators. The key to successful upgrades often lies in the quality of the parts used.

All Aftermarket Parts Are Not Created Equally

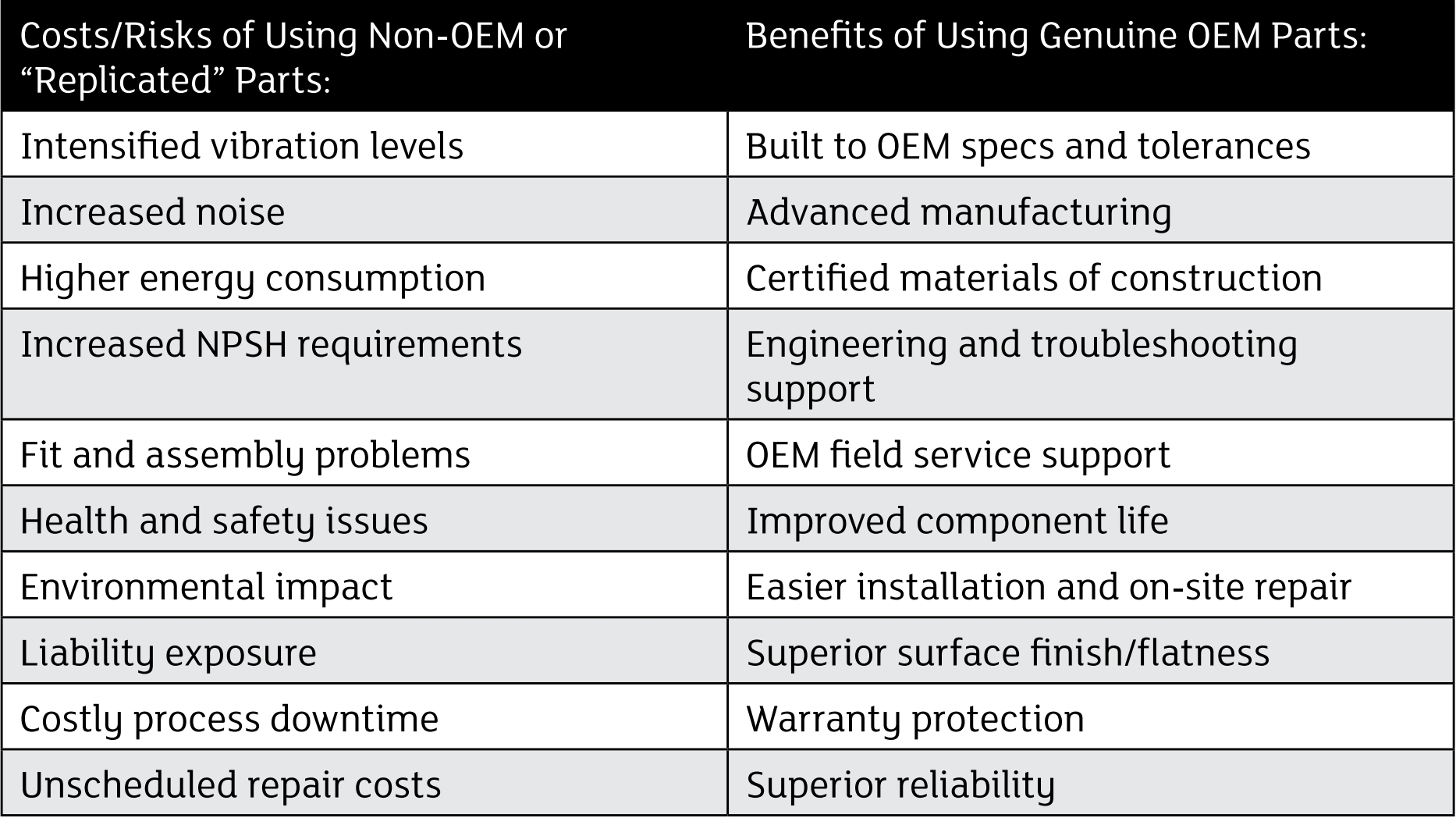

Precise tolerances are key to the performance of rotating equipment. Even the smallest variance can generate inefficiencies within a process flow. Using non-OEM components increases the risk of equipment failure, but these risks can be avoided by using genuine OEM parts.

OEM parts are machined accurately using advanced metallurgies. They are custom engineered to fit the precise tolerances of each machine. The manufacturing processes of unlicensed fabricators fall short of an OEM’s standards and original engineered design intent.

The Risks Associated With Imitation Parts

While it may be tempting to pay a little less for non-OEM replacement parts, it is important to consider the potential hidden costs of using replicated parts. Any cost savings received initially could ultimately lead to increased costs for repairs and increased energy consumption.

Return on Investment From Upgrades vs. Purchasing New Equipment

The updates previously referenced can be accomplished in a matter of days, at a fraction of the cost of buying new equipment, providing the following benefits:

- Lower operating costs: Ensuring that pumps and compressors operate at BEP minimizes vibration and reduces energy costs.

- Lower maintenance costs: Upgrading the key components with new OEM parts that are warrantied extends maintenance intervals and reduces overall maintenance costs.

- Increased plant uptime: Many refineries run operations around the clock, and plant uptime is the true measure of all optimization efforts.

Global demand for diesel fuel continues to increase. Many refineries are contemplating ways to meet demand with new market opportunities, such as renewable diesel. Any plant considering increasing its output, or varying its processes to accept renewable feedstocks, should rerate and upgrade its rotating equipment. The success of most upgrades often comes down to the quality of the parts used.

References

- farmdocdaily.illinois.edu