Proper ingredient transfer equipment is crucial in maintaining optimal efficiency and high product quality while balancing operating costs. Food and beverage processors have a difficult task making purchasing decisions when installing new equipment or upgrading outdated equipment. A four-ingredient recipe exists to select the right pump technology for food and beverage applications.

Food and beverage processing has no shortage of options for material pumping. The options can seem overwhelming for users, from the industry’s new twin screw pumps, the reliable rotary lobe pumps, the adaptable electric and air-operated diaphragm pumps, the powerful piston pumps, and so on. There is a configuration available in the market to meet a user’s needs. The following considerations will steer users in the right direction.

1. Flow Rate

The volume flow rate is determined by multiplying material velocity and tubing size to determine gallons/liters per minute.

Determining flow rate is critical in selecting the perfect pump. A pump that is too small for the application will run too hard or too hot, which may cause pump failure. A pump that is too large will incur larger purchase and operating costs. As a general rule, pumps should operate at 30 percent to 60 percent of maximum capacity. This reduces unnecessary wear due to high speeds and allows for future expansion or process capabilities if needed. This holds true for rotary lobe, diaphragm, twin screw, sine pumps, and just about any other pump that may be installed in an application.

.jpg) IMAGE 1: Large particle AODD pump (Images courtesy of Graco)

IMAGE 1: Large particle AODD pump (Images courtesy of Graco)2. Product Characteristics

Viscosity

Fluid viscosity is the most concerning characteristic to pump operators. The above flow rate performance rating for pumps will decrease with material viscosity. Most pumps are rated for maximum flow rate with water at 1 centipoise (cP). Most food ingredients are thicker than water, reducing maximum output anywhere from 5 percent to upwards of 25 percent performance reduction. Typically, centrifugal pumps are used for lower viscosity fluids and pumps such as piston, lobe, diaphragm and others are used for higher viscosity liquids.

Material viscosity will affect how well the pump can load material into the inlet of the pump as well as output. Lobe pumps do not create significant inlet suction and have a difficult time priming higher viscosity liquids. Electric or pneumatic diaphragm pumps and peristaltic pumps are able to load high viscosity materials into the pump with the suction they produce. If the material’s viscosity exceeds 100,000 cP, a ram unit will be required to apply downward pressure to material into the pump when unloading from containers.

Abrasion

Material abrasiveness can wear out pump components easily, especially when using centrifugal-style pumps, which causes higher repair costs. Material with high sugar content will quickly wear out components compared to other materials. Lobe pumps will sometimes use specialty materials and coatings to properly handle this increased abrasion but can still struggle with leaking rotary seals and rotor wear over time. Diaphragm pumps, which do not employ a rotary seal or rotating components, handle abrasive materials much easier than the tight tolerances required in lobe pumps.

Material shear

In applications like tomatoes, pie fillings, ricotta cheese, meat and poultry, users should be aware of material shear. Diaphragm, peristaltic and sine pumps are gentle on materials and will not shear the material being pumped like a centrifugal, lobe, twin screw or other rotary-style pump. This is important for users whose products are affected by shear and heat where it can alter the final product produced by the equipment.

Particle size

Users should be aware of any solids or particles within the material being transferred. Food ingredients such as salsa, fruit fillings and others have large-sized pieces of food within the liquid. Diaphragm pumps with flapper checks and peristaltic pumps are designed to handle solids upward of 4-plus inches in diameter. Rotary pumps can handle some solids, but not of any significant size and often damage particles and degrade the material due to the pump style and operating speed.

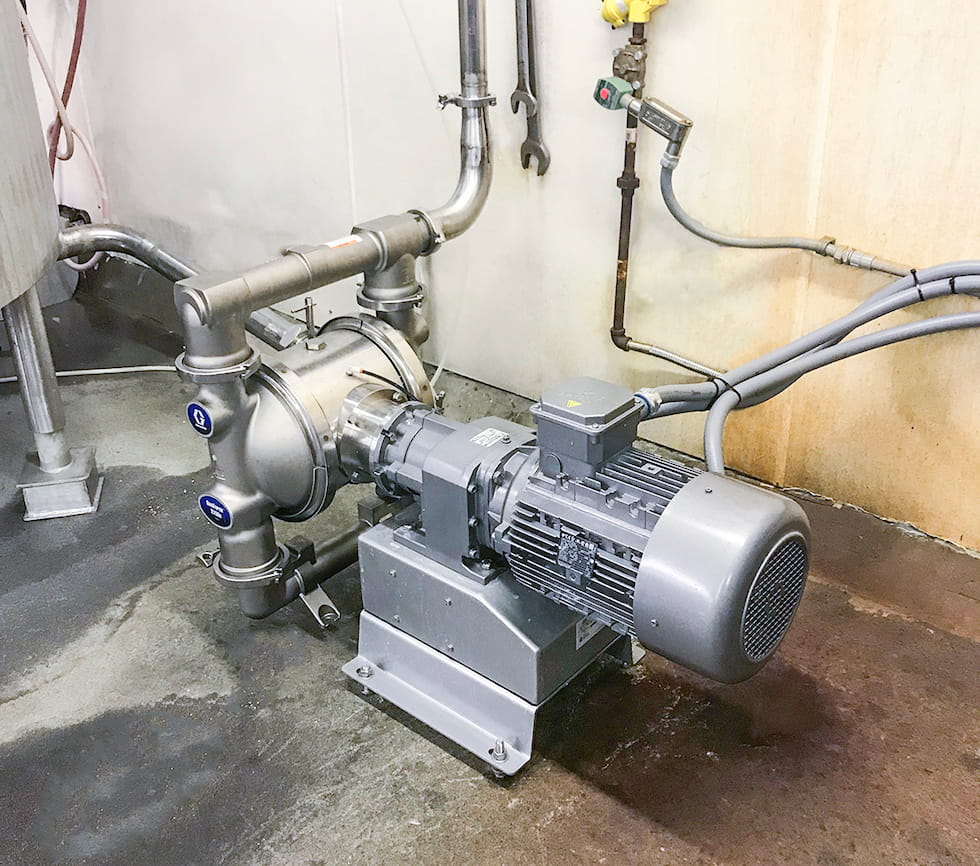

.jpg) IMAGE 2: An EODD pump in an installation

IMAGE 2: An EODD pump in an installation3. Construction Materials

Ensuring the pump materials are compatible with the ingredient being transferred will keep the pumps operating for a long time. Most sanitary pumps are built with stainless steel, but all use some sort of elastomer seals that are more susceptible to compatibility issues. In the meat and poultry business, many elastomers do not hold up well to animal fats and oils in the material.

Pump construction and elastomers also need to be compatible with the facility cleaning solutions and clean-in-place (CIP)/clean-out-of-place (COP) requirements. Many faults occur when a pump elastomer or seal is compatible with the food ingredient but cannot handle the caustics used to clean the equipment.

Pump clean-ability and plant cleaning procedures must be considered to select the right pump. Does the facility require a pump that is capable of being cleaned in place and not removed? This may direct users toward rotary lobe or other rotary pumps designed for CIP capability. Diaphragm pumps can be cleaned in place but are material dependent. Many plants are now using steam-in-place cleaning—meaning all pump components must withstand the extreme steam temperatures run through the pumps.

4. Approval Requirements

Are there are any equipment approvals required for the process? United States Food and Drug Administration (FDA) approval and design is the most widely used standard in the food industry. Ensure equipment meets all FDA standards and complies with FDA Code of Federal Regulations (CFR) Title 21. Many other approvals may drive specific pump selections.

When processing solvents proof or atmosphere explosible (ATEX) approval is required. European manufacturers may require equipment meeting European Framework Regulations (EC) 1935 approvals, and many personal care and pharmaceutical facilities require U.S. Pharmacopeia (USP) Class VI approved components. The approvals are driven by the material being produced and how the customer will ingest or use the product.

There are many factors driving equipment selection for food and beverage applications. It is important that material fluid handling requirements are understood completely before selecting a pump.