Millions of people across the globe face escalating challenges in accessing clean drinking water. Factors such as demographic shifts, economic development, overexploitation of resources and climate variations contribute to the worsening problem of water scarcity. In today’s landscape, where energy consumption, carbon dioxide emissions and global water scarcity intersect, desalination serves as a crucial solution for meeting global freshwater demands. Contemporary approaches prioritize optimization and pursue maximum efficiency in plant configurations.

While reverse osmosis (RO) remains the primary method for seawater desalination, its energy requirements pose a challenge. A crucial factor in driving overall specific energy consumption (SEC, kilowatt-hours [kWh]/cubic meters [m3] produced fresh water) hinges on equipment selection and its performance, allowing for increased efficiency with modest investment and swift returns.

Increasingly, desalination plants require flexibility to adjust to fluctuating demands and operating conditions throughout the year amid industrial needs, rapid population growth and increased population density. Stakeholders seek strategies to optimize desalination facilities with the goal of improving energy efficiency and effectively balancing power usage.

Two critical components within a desalination plant are the high-pressure pumps (HPPs) and the energy recovery devices (ERDs). The HPPs are the primary energy consumer, accounting for up to 60% to 70% of the total energy consumption in desalination facilities. Ensuring optimal efficiency in high-pressure pumps across all operational scenarios and monthly variations is crucial for maximizing the reduction in power consumption. Energy recovery devices also play a key role in reducing the SEC by recovering part of the energy used in the desalination process. Notably, isobaric devices have demonstrated superior efficiency and performance among existing technologies.

Efficiency Evolution in High-Pressure Pumps

There are two categories of HPPs in desalination plants: centrifugal pumps and axial piston pumps (positive displacement family). These differ fundamentally in technology, affecting their performance in membrane applications.

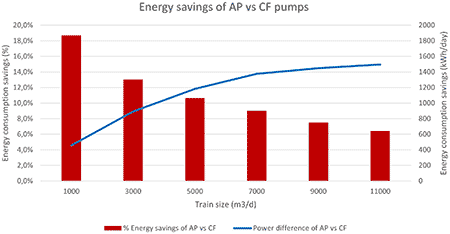

Centrifugal (CF) pumps enhance efficiency with size, whereas axial piston (AP) pumps—standardized and deployed in parallel—ensure consistent efficiency regardless of plant size. A study comparing the energy efficiency of both pump types across various train sizes (outlet pressure of 65 bar) unveiled a potential energy savings of 19% for a 1.000 m3/day train and 5% for a 15.000 m3/day train.

Even though the energy efficiency gap between AP and CF pumps decreases with larger flows, the absolute amount of power saved (kWh’s) shown in Image 1 increases as the volume of water that flows through the pumps also increases.

Variations in Desalination Plant Operating Conditions

Pumps in desalination plants do not run at constant flow and pressure conditions; they are exposed to variations, which can occur over short and long time frames. These variations are driven by a variety of parameters such as seasonal changes (seawater temperature and salinity level), which imply a pressure variation in the membrane inlet, and variations in water demand, which lead to changes in production requirements.

AP pumps stand out for their ability to maintain nearly constant efficiency under any condition. This capacity to adapt to any system demands with negligible impact on energy efficiency allows for enhanced energy consumption compared to other technologies.

Parallel Installation: The Flexibility of Axial Piston Pumps

When system pressure increases, AP pumps maintain a constant flow at the desired pressure without requiring any adjustment. Unlike other technologies, changing the flow rate on one AP pump does not impact the flow rate of other parallel-coupled AP pumps, eliminating potential system compatibility issues and flow disruptions. This allows for flow regulation to be performed on just one pump when using multiple AP pumps in parallel. The total flow for all pumps together can be calculated simply as the sum of the individual pump flows.

Due to their ease of control, operation and superior efficiency, AP pumps are typically configured for parallel installation to achieve the desired capacity efficiently, thus enhancing plant flexibility and availability. This setup offers the additional advantage of low voltage in both motors and variable frequency drives (VFDs).

In this modular setup with AP pumps installed in parallel, VFDs could be installed in just one or two pumps to regulate any system variations while the remaining pumps operate directly online (DOL), thereby reducing efficiency losses and VFD capital expenditures.

Field Experience: Maximizing Efficiency, Uptime & Space

A Spain-based engineering company specializing in reverse osmosis water treatment solutions was building a seawater reverse osmosis (SWRO) system for a large well-boat in Norway that needed to delouse salmon with freshwater treatments. There were three primary requirements for the desalination plant:

Provide 5,000 m3 per day while maximizing the boat’s limited space.

Ensure the highest energy efficiency to maximize their users’ return on investment.

Ensure the best equipment availability, quick maintenance and system reliability to mitigate the risks of sea lice infestation and amoebic gill disease.

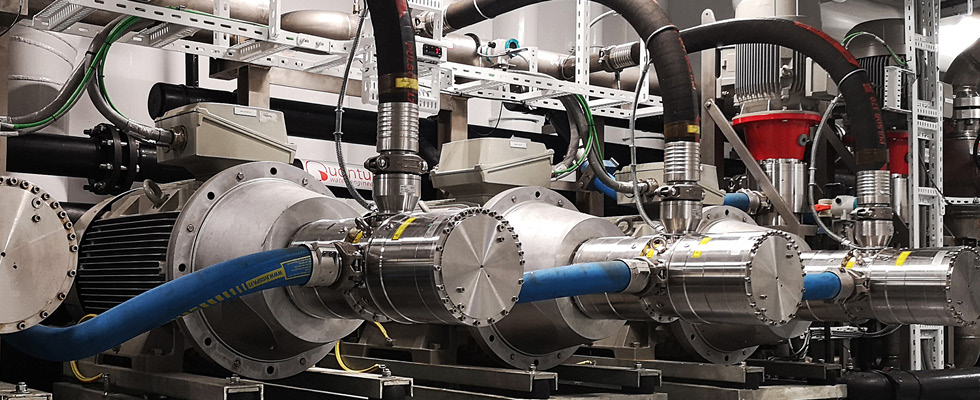

To meet these challenges, the company designed a two-train SWRO plant. Each 2,500 m3 train is equipped with two parallel installed high-pressure axial piston pumps and two parallel installed active isobaric ERDs, each connected to a VFD.

These components are particularly well suited for uptime requirements and situations where space is limited. The ultra-compact design of the AP pumps allows for on-site maintenance, while the active ERDs’ three-in-one design combines an isobaric pressure exchanger, booster pump and motor for extremely compact energy recovery.

The general manager of the company highlighted that the combination of AP pumps and active ERDs was crucial in meeting the client’s goals for the desalination plant. This solution offers reliable, low-energy consumption with minimal maintenance, and delivers high production capacity in a compact design.