Follow this guide to properly align and install vertical turbine pumps.

04/07/2015

Vertical turbine pumps have multiple components that may make alignment complicated in American Petroleum Institute (API) and industrial applications. Tolerances cannot be made tight enough to ensure proper alignment because the required tolerances cannot be achieved by manufacturing accuracy alone. It takes skill, time and patience to make the minor adjustments required to ensure proper alignment. When aligning the components of a vertical turbine pump, end users must understand and evaluate key considerations for the following designs:

- VS-1 tank mounted vertical turbine booster pump (single casing) utilizing a vertical P-Base driver with integral thrust bearing design

- VS-6 vertical turbine booster pump with suction barrel (double casing) utilizing a vertical P-Base driver with integral thrust bearing design

Alignment

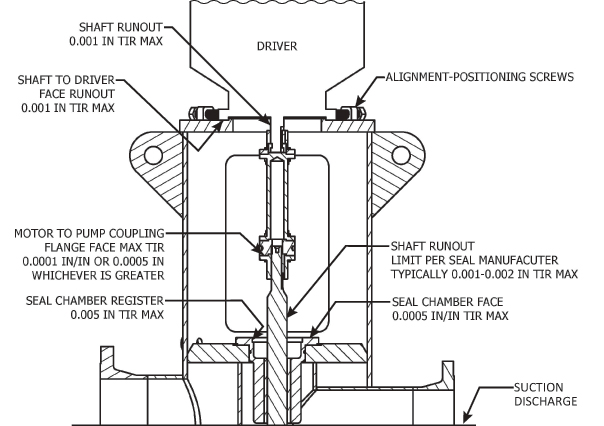

The pump driver may consist of an electric motor, vertical gear or steam turbine that incorporates a vertical solid shaft design mounted on the pump’s discharge head. The vertical solid shaft driver must be supplied with special shaft and base flange tolerances. API 610 11th Edition specifies the tolerances in Figure 1. The maximum shaft runout and shaft to driver face perpendicularity of 0.001 total indicated runout (TIR) are most important. The 0.005 TIR maximum axial float may be achieved in most cases, but some extra high thrust designs may require greater axial float. The pump discharge head should be welded according to specification requirements. If it is constructed of carbon steel, a post-weld heat treatment (PWHT) process is recommended after fabrication and prior to machining to prevent warping after the final machining process. Users should give special consideration to the driver to discharge head female/male register fit, typically referred to as the National Electrical Manufacturers Association (NEMA) driver “AK” dimension. Figure 1. The drawing shows the critical dimensions. Ensuring the proper seal alignment between the pump and driver is the best safeguard for prolonging seal life and maximizing the mean time between repairs.

Figure 1. The drawing shows the critical dimensions. Ensuring the proper seal alignment between the pump and driver is the best safeguard for prolonging seal life and maximizing the mean time between repairs.