Last of Two Parts

05/30/2014

Last of two parts.

In my April 2014 column in Pumps & Systems, I quizzed readers, asking if the pump suction behavior depended on the discharge (system) side of a pump. This quiz also referenced a video that can be viewed at www.pump-magazine.com and go to Q&A, Question 120.

Image 1. Dr. Lev Nelik conducts the experiment shown in the video.

Image 1. Dr. Lev Nelik conducts the experiment shown in the video.The Best Reader Answer

The best answer received was from Jim Gagnon, P.E., senior engineer, from CH2M HILL in Cincinnati, Ohio.Gagnon’s Response

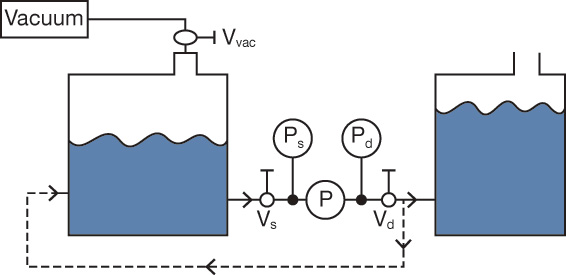

I watched the YouTube video that you posted, and I think I have the solution. In the first experiment, the pumped flow rate decreased when you throttled the suction-side valve because closing the valve added dynamic head to the system. The result is that the operating point moved to the left on the pump curve, and the flow rate decreased. Figure 1. System sketch illustrating the example in the video

Figure 1. System sketch illustrating the example in the videoNelik’s Response

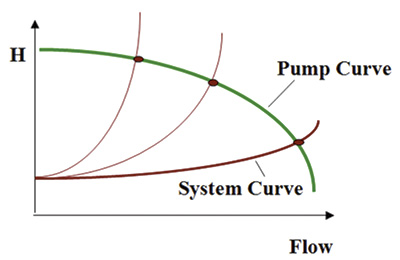

You are correct, Jim! Normal flow control of the pump/system is accomplished by closing or opening the discharge side valve—almost never by its suction side. Closure of the valve increases the losses across the discharge valve, and its opening decreases the losses. New system curves are created that intersect the pump curve at new operating points (see Figure 2). Figure 2. Connection between the discharge performance (H-Q) and cavitation—NPSHR

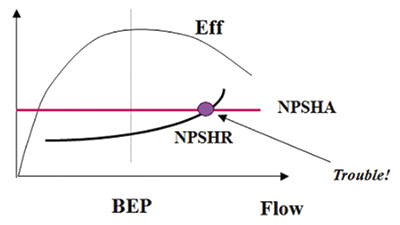

Figure 2. Connection between the discharge performance (H-Q) and cavitation—NPSHR Figure 3. Point at which cavitation develops

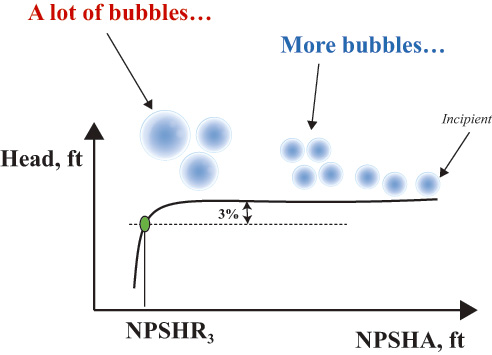

Figure 3. Point at which cavitation develops Figure 4. Development of cavitation, starting from the incipient bubble formation and eventually developing to highly unstable bubble activity, their collapse, and damage of the impeller blades

Figure 4. Development of cavitation, starting from the incipient bubble formation and eventually developing to highly unstable bubble activity, their collapse, and damage of the impeller blades