With the Environmental Protection Agency (EPA) regulations in April 2024 for per- and polyfluoroalkyl substances (PFAS), many questions have been brought up as to how to test the various media in the market that are being used and new ones developed for PFAS removal.

Q: Can laboratory testing be conducted on various media to determine feasibility and design for PFAS compounds?

Laboratory tests such as adsorption isotherms and the rapid small scale column test (RSSCT) can be used to determine feasibility of the media, but they have several limitations. Due to the extremely low levels of PFAS compounds being regulated in drinking water (part per trillion levels), running an adsorption isotherm test is extremely difficult. The data tends to be scattered, which can and does lead to data that is difficult to interpret. The adsorption isotherm will only give an overall PFAS capacity for the media but will not give any kinetic information. The RSSCT can be used to test various media, but the method in general was developed for granular activated carbon (GAC) and has not been validated for other media. The method is conducted using water from the site and therefore does have limitations if the water quality varies seasonally.

Q: Is there another test that can overcome the limitations of the adsorption isotherm and RSSCT?

Yes, an on-site pilot trial can be used to evaluate various media side by side and account for any seasonal water quality variations.

Q: How is the pilot test designed to ensure the data developed during the study will accurately depict the full-scale operation?

It is critical that parameters such as the hydraulic loading rate (HLR) and empty bed contact time (EBCT) being utilized in the full scale are also utilized in the pilot unit. The hydraulic loading rate in gallons per minute per square foot (gpm/ft2) is calculated using the diameter of the vessel and the flow rate using the following equation:

HLR (gpm/ft2) = flow rate in gallons per minute/∏ * (diameter/2)2

Equation 1

The empty bed contact time is calculated using the following equation:

EBCT (minutes) = volume of media in gallons/flow rate in gpm

Equation 2

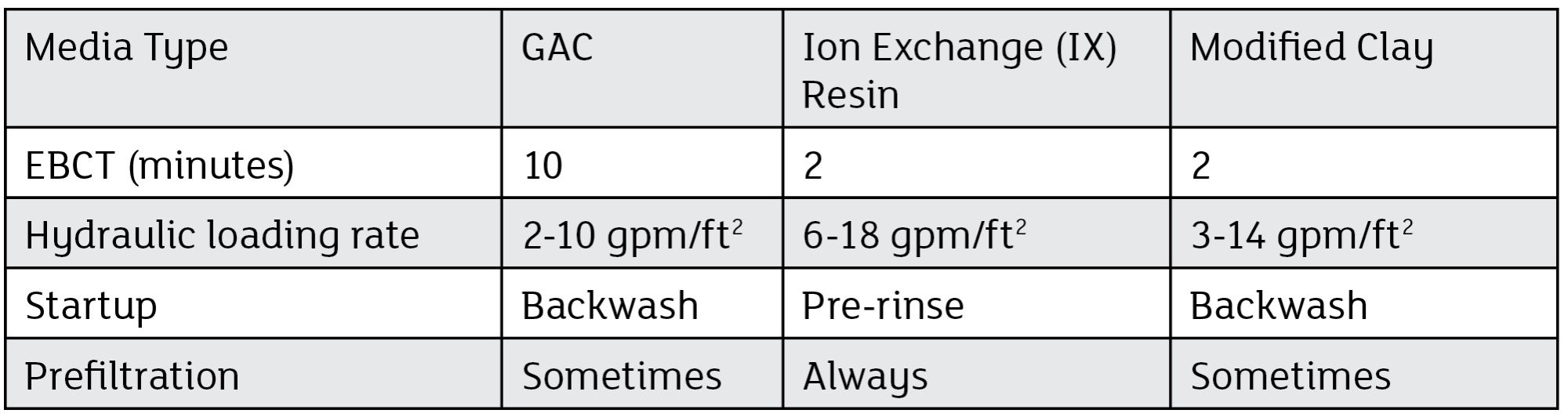

The recommended HLR and EBCT will differ by media, so it is important to understand the media supplier recommendations prior to designing the pilot unit. Table 1 shows the ranges of HLR and recommended EBCT for various media, as well as other considerations in terms of startup and prefiltration requirements.

Q: Are there any properties of the media that should be taken into consideration in terms of operation and data analysis?

Yes, the density of the media is extremely important since the EBCT is a volume-based calculation, but media such as GAC can have varying densities and are sold on a per pound basis. Table 2 shows an example of how the pounds of GAC can vary greatly due to density differences between the products.

Q: Should any data or test reports be requested from the media suppliers prior to pilot testing?

Yes, technical data sheets should include all physical properties specified, as well as bed expansion and pressure curves where applicable. For the media being tested, laboratory data on the specific sample should be requested, as well as enough sample that a third-party lab test can be conducted to verify the media meets the specification.

Q: Are all media prepared that same way prior to loading into the columns for testing?

No, each media can and does have procedures that will differ from one to the next. Media such as GAC must be soaked overnight to degas the carbon, which involves removing air within the pore structure. If the GAC is not degassed properly, the product will not work as designed. Media such as IX resin needs to be rinsed generally for about 20 bed volumes of water prior to use. Both GAC and the modified clay media need to be backwashed according to the manufacturers’ recommendations to remove fine particles and stratify the bed.

Q: During backwash and initial startup, is there any value to collecting water samples?

Yes, various parameters such as pH, organics and inorganics can and should be tested to determine how much water, if any, will need to be treated at full-scale startup.

It is well known that GAC will cause an increase in pH at startup due to alkaline ash within the GAC from the starting material and due to an IX effect based on influent water quality. There are no standard tests that will determine the magnitude and duration of the pH increase. Procedures such as acid washing of the GAC will not eliminate the pH increase.

GAC and modified clay are produced from materials taken from the earth and will have various inorganic compounds present. GAC are known to leach arsenic, which should be monitored to determine magnitude and duration. Standards such as Prop65, NSF 61 and NSF 42 cannot guarantee arsenic concentrations in the soak or backwash because levels will be below the maximum containment level (MCL).

Q: How often should samples be collected during the pilot trial?

During initial startup, samples should be collected to determine pH and metals leaching until those values are within acceptable limits. As for PFAS compounds, the sample frequency will be determined by the compounds and concentrations, as well as other compounds present.

For GAC, it is important to understand the water quality—specifically other organics present. In many cases, specific compounds are not known, but total organic compounds (TOCs) are known. Higher TOC concentrations are most likely going to negatively affect performance for the PFAS compounds. For IX resin, other anions such as nitrate and sulfate will negatively affect performance. Suppliers should be able to provide mathematical modeling estimates to assist the end user in setting up a sampling routine.

Q: What can be determined by analyzing the effluent water samples?

The effluent water data will show breakthrough of the PFAS compounds as well as other compounds of measurements like TOCs, which will give the end user information on the order of breakthrough as well as the times to breakthrough. This information will allow the end user to compare various media types (GAC, IX, modified clay, etc.) as well as compare within media types (GAC to GAC).

In most cases, the data is plotted on a bed volumes treated basis in an effort to normalize the data. Although this does provide a nice visual interpretation of the data, the more important comparison is the cost per volume of water treated. A media could potentially treat five times the volume of water compared to another but come at five times the cost, making them equal on a cost per volume of water treated basis.

Q: Is there any value in collecting the spent media after the pilot trial is completed?

Yes, disposal of spent media is always a concern, so collecting the spent media will allow that media to be tested for disposal using technologies such as reactivation, incineration and some of the newer destruction technologies.

Although the laboratory tests will generate some information, the limitations of these methods will not provide accurate information to design a full-scale system. A great deal of information can be obtained with a properly designed and operated pilot study from water quality effects and media comparison to media disposal.