Inherent arc hazards are often overlooked in medium-voltage AFDs

Eaton

12/28/2017

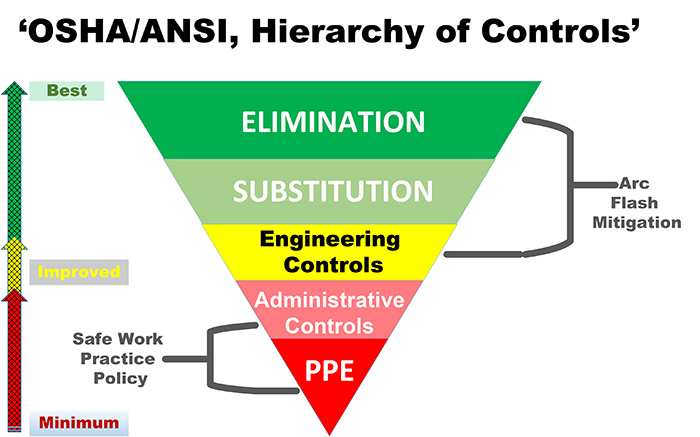

The Fire Protection Research Foundation reports fatal injuries related to electrical incidents from 2004 through 2010 resulted in 1,494 fatalities, 29 percent attributed to direct contact with wiring, transformers and electrical components. From 2011 to 2013, 43 percent of fatalities were attributed to indirect contact and 54 percent attributed to direct contact. There is a systematic approach to minimizing or mitigating the risk of electrical injury. The Occupational Safety and Health Administration (OSHA) Hierarchy of Controls (see Figure 1) outlines the following controls from highest level to lowest: elimination, substitution, engineering controls, warnings, administrative controls and personal protective equipment (PPE).

Figure 1. OSHA hierarchy of controls

Figure 1. OSHA hierarchy of controls