Both variable frequency drives (VFDs) and variable speed drives (VSDs) are common terms used in the pump industry. A VFD and VSD both vary the speed of a pump, and they can sometimes be used in reference to the same technology but are other times used to refer to different technologies. Confusing, right?

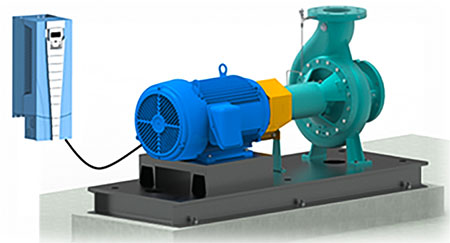

A VFD varies the speed of an electric motor by controlling and varying the frequency and voltage supplied to an electric motor, often a 3-phase alternating current (AC) induction motor. By controlling and varying the voltage and frequency supplied to the motor being used, the rotational speed of the motor can be increased or decreased above its rated speed and the pump speed varies accordingly. In most cases, VFDs are used to decrease the motor speed below its rated speed. Check with the pump, motor and VFD manufacturers prior to running the equipment above the rated speed.

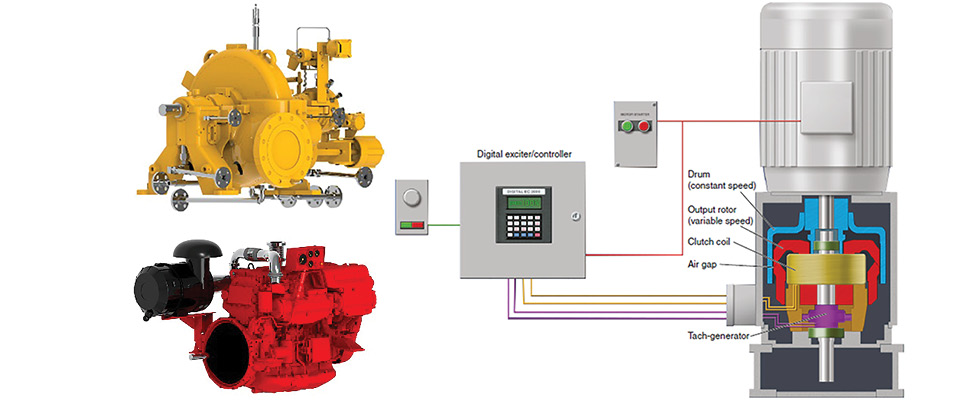

A VSD is a broader term that includes any VFD, driver or drive that can control the speed of the machine or motor it is connected to. Two examples of drivers that are inherently variable speed are the steam turbine and the combustion engine (Image 2). There are other types of drives that are installed between the motor and pump and only reduce the speed of the pump shaft while the electric motor operates at full speed. Two examples of these drives are eddy current couplings (Image 2) and fluid couplings.