The valve is an inconspicuous element in the pump circuit; yet, like a fuse in a power circuit, it is essential for plant safety. Given its operating principle, it also makes a valuable contribution to energy efficiency.

Most centrifugal pumps operate with a constant speed along a fixed curve. The pumps are integrated into plants with variable discharge flows. The variable flows lead to working areas where process-related flow rates are below the required pump-specific minimum flow.

The pump minimum continuous flow (MCF) is the lowest permitted flow rate a centrifugal pump can operate at permanently without damage. The MCF is the lowest permitted flow that complies with the pump and plant’s requirements regarding a safe and economic operation.

To ensure the required flow rate does not fall below the permissible minimum, it is common to install a bypass with an orifice between the pump’s discharge branch and the first shut-off device in the pressure line. The orifice device permanently allows the constant minimum flow to pass to recirculation.

The orifice solution permits a constant loss of flow rate that considerably reduces the efficiency of the pump assembly. Based on economic and ecologic aspects, this solution is only acceptable for smaller low-pressure pumps with low minimum flow requirements.

Large Plants & High Pressures

For assemblies with larger pumps and higher operating pressures, one of the following solutions are applied:

- Systems with an actuated control valve, with flap valve and according measurement technology

- The so-called automatic recirculation check valve that practically includes all the above-mentioned functions of an actuated control valve.

Systems with actuated control valves can be relatively complex and expensive.Solutions that incorporate automatic recirculation check valves are considerably simpler and more robust.

According to a calculation by a German manufacturer, investments in pump systems with integrated automatic recirculation check valves, compared to fixed orifice solutions, can be amortized in as little as one year.

Considerable energy and operating costs savings are possible with the application of automatic recirculation check valves in the pump protection system.

Operating Principle

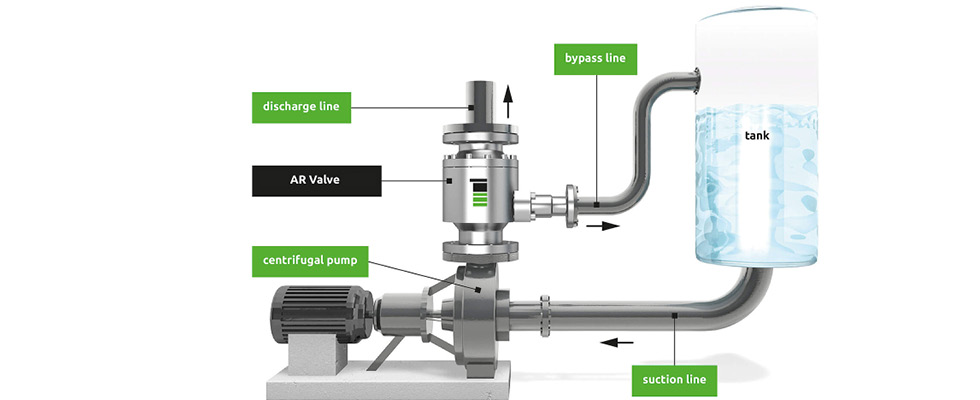

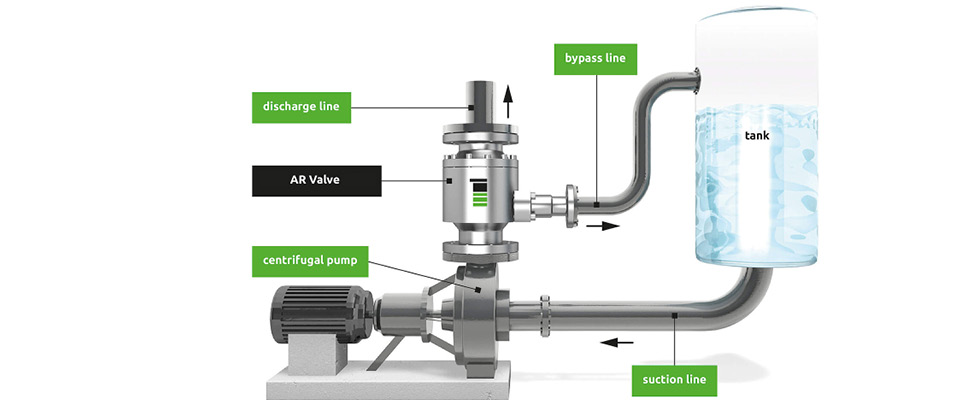

Automatic recirculation check valves are mounted on the discharge branch of the pump or in the discharge line near the pump. The bypass branch of the valve is connected to the bypass recirculation line. The function of the valve operates on process demand flow. In start-up conditions with no demand flow to process, the valve will allow the MCF through the bypass. As the process demand is opened, the valve will modulate flow between the process and bypass branch, ensuring the MCF is achieved at all process demand points. As the process demand exceeds the MCF, the bypass will fully close and all flow through the valve will be sent to process.

The valve operates in reverse when process demand is decreased. If the process demand flow rate falls below the required minimum flow, the valve automatically reopens the valve bypass and the determined flow rate can be discharged through the bypass line.

The automatic recirculation check valve ensures that the entire pump flow rate (process flow plus bypass flow) is greater than the required minimum flow at all times.

In this scenario, the pump is always protected from low flow conditions.

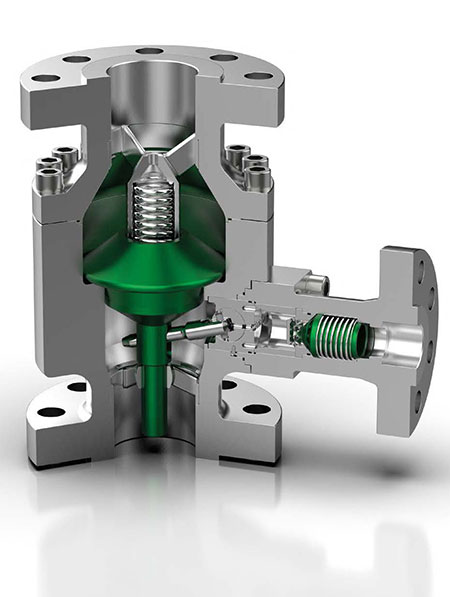

Compared to a fixed orifice solution, the automatic recirculation check valves regulate the bypass flow rates at a permanent minimum, and the pump assembly is protected safely. Pump head losses are minimized by automatic recirculation check valves. The pump assembly’s efficiency remains high and operating costs of the plants are minimized. Automatic recirculation check valves consist of a three-way body with three integrated flange connections that are the interfaces to the pump assembly. Internally there is a guided and spring-loaded valve cone that provides the check function and prevents backflow of the medium through the pump. The stroke of the check valve is reliable and mechanically operates the bypass lever. The operation of the bypass lever regulates the opening and closing of the bypass branch and consequently the bypass flow.

Compared to the operating pump pressure level, the pressure level in the bypass line is considerably lower (since the bypass line leads to either the tank or the suction line). The bypass internals of the valve provide an additional feature of pressure reduction in the bypass line. This pressure reduction feature prevents flashing and cavitation in the bypass line and return tank.

Advantages & Applications

Automatic recirculation check valves are process fluid controlled and do not require any external energy source. The valves are highly reliable, robust and low maintenance.

Given these characteristics, automatic recirculation check valves are integrated in many security-relevant industrial areas including:

- Boiler feed water or cooling water systems

- Petrol chemistry and refrigeration technology

- Potable water supply and wastewater disposal

- Offshore and nuclear power applications

- Steel production, pulp and paper plants, and more

The application of automatic recirculation check valves underlines the relevance and reliability of these pump protection units especially in nuclear power.

Automatic recirculation check valves are applicable for almost all liquid mediums in industrial practices where centrifugal pumps are used. The temperature range extends from minus 450 F to plus 750 F.

The design of the automatic recirculation check valves is in accordance with the requirements of different international standards, regulations and user specifications from the respective industrial sectors. The standard nominal size range extends from 1.25 inches to 16 inches at a nominal pressure range from American Society of Mechanical Engineers (ASME) 150 to ASME 2500.

According to technical and user requirements, automatic recirculation check valves are made from materials ranging from carbon steels to super-duplex steels. The interior parts are made from stainless steel.

Given the simple design of the automatic recirculation check valves, plant-specific installation conditions (i.e. piping connections) are often considered.

Every valve undergoes flow testing after manufacturing. The valve functions and the MCF flow requirements are tested on a sophisticated test stand. The tests simulate the pump design conditions the valves are designed to protect.