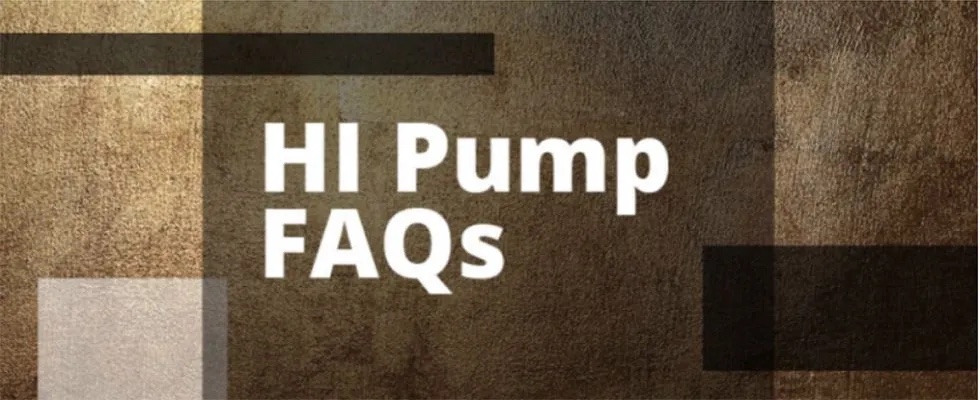

IoT stands for “Internet of Things,” and it is sometimes referred to as the industrial Internet of Things (IIoT) in industrial applications. This refers to the interconnected network of sensors, devices and systems used in industrial settings to collect, communicate and analyze real-time data. In pumping systems, connected sensors monitoring variables such as vibration, pressure, temperature, power and flow rate can communicate this data to edge computers and to the cloud for analytics. This enables abnormal or inefficient system operation to be detected and quickly corrected.

Image 1 illustrates multiple IIoT devices communicating data to handheld edge computers and cloud servers, enabling the operation of both devices to be monitored and analyzed.

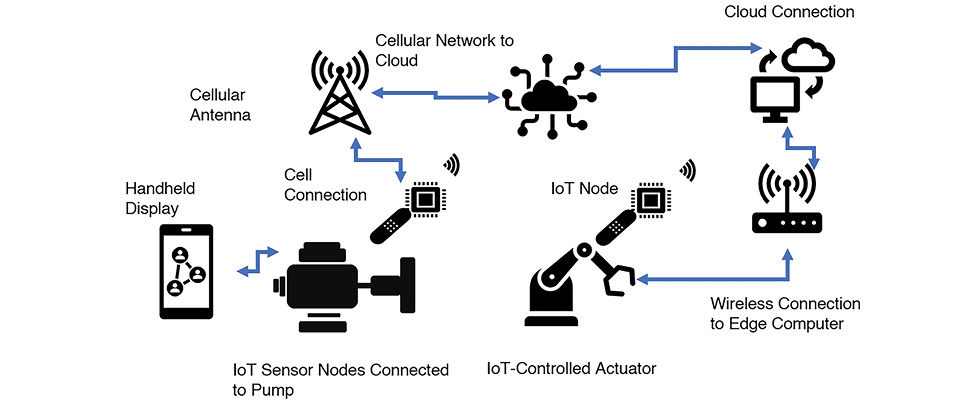

An example of a simple application of IIoT is an automatic notification sent to a system operator via their smartphone, alerting them that a system parameter has gone outside the acceptable range. This allows the operator to focus attention on that specific system to bring the operation within specification. As illustrated in Image 2, the operator can be alerted via text message and can reply to indicate if they will be handling the situation or if it needs to be escalated. Depending on the system and control design, the operator may not even need to be on-site to correct the operational issue.

In this context, utilizing IIoT in pumping systems is valuable not only for maintaining efficient operation, but also for identifying adverse operating conditions and predicting or preventing failure. In the pumping industry especially, failure of a system can lead to a complete shutdown of the facility in which it is being used. The continuous data collection provided by IIoT supports fault identification and predictive maintenance, as potential issues are identified and addressed before they lead to system failures, thus minimizing unplanned downtime, lost production and maintenance costs.

From an energy efficiency perspective, IIoT can be used to facilitate energy or resource optimization analysis of connected data. Data-driven adjustments to when equipment is operated, when it is staged on and off or at what speed the equipment is operated are all examples of how IIoT can be utilized to enable reduced energy consumption and operational costs.

For more information on IIoT and solutions for pumping systems, refer to HI’s guidebook, Internet of Things: Solutions for Pumping Systems, at pumps.org/guidebooks.