What types of pumps are used in the mining industry?

When mining ore to extract useful minerals from the earth, pump systems are depended on to make sure that day-to-day operation runs efficiently. There are numerous types of pumps that are utilized in the mining industry.

One common type of pump is a centrifugal slurry pump, which is suitable for pumping liquid containing solids. Slurry is a mixture of solids (specific gravity typically greater than 1) in a liquid carrier, usually water.

The following are slurry characteristics:

- Slurries are often used to transport solids.

- Properties of the solids and the liquid, as well as the number of solids, are variable.

- The solids particle size may vary from a few micrometers to hundreds of millimeters.

- Depending upon size, solids tend to settle below different threshold transport velocities.

- Slurry may behave like a Newtonian or non-Newtonian fluid.

- It may be abrasive and/or corrosive depending on the composition.

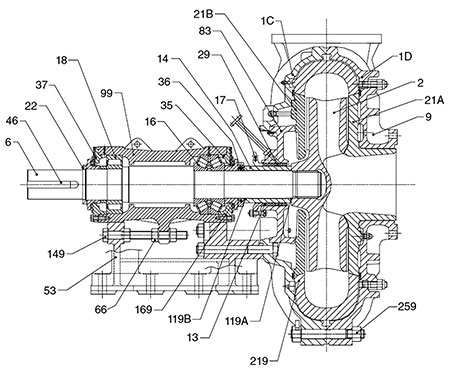

Slurry pumps (Image 1) are typically used to transport slurries with specific gravities up to 5.3 and solids concentration between 2% and 50% by volume.

Slurries with solids of wood, paper, specialized chemical particulates, wastewater and other organic

materials also exist but are not the focus of this article.

Due to the varying nature of the slurry and possible application, the construction will vary but they are generally designed to be robust. The parts in contact with the slurry are often replaceable and typically made of wear resistant alloys or elastomers. Slurry pumps are overhung impeller types and can be frame mounted, cantilevered wet pit or submersible types.

For more information on slurry pumps, refer to “American National Standards Institute/Hydraulic Institute (ANSI/HI) 12.1-12.6 Rotodynamic Centrifugal Slurry Pumps for Nomenclature, Definitions, Applications and Operation” at pumps.org.