Heat exchangers are commonly used for a wide range of purposes in the food industry, from pasteurization, sterilization and evaporation to general heating and cooling. With various types and designs available from numerous manufacturers, choosing the right solution from the right supplier can seem daunting. However, posing the right questions at the beginning of the procurement and design process can prevent future misunderstandings and ensure the optimal product or system is acquired. Here are nine key questions to ask any potential heat exchanger supplier.

1. Do I actually need a heat exchanger?

Although heat exchangers are the preferred option for many food processing processes that include heat (pasteurization, sterilization, evaporation, etc.), it is a good idea to consider alternatives. In some situations, a straightforward heating element or refrigeration system may be more suitable. A creditable heat exchanger supplier will not try to sell a solution that is not needed.

2. What type of heat exchanger best suits my needs?

The simplest option is plate heat exchangers (PHEs), which consist of combinations of plates and gaskets through which the product and the heating or cooling medium move. They are relatively simple and cost effective and do a good job with simple fluids like milk and thin oils. However, for more viscous substances, non-Newtonian fluids and processes requiring high levels of heat transfer, tubular heat exchangers are more effective.

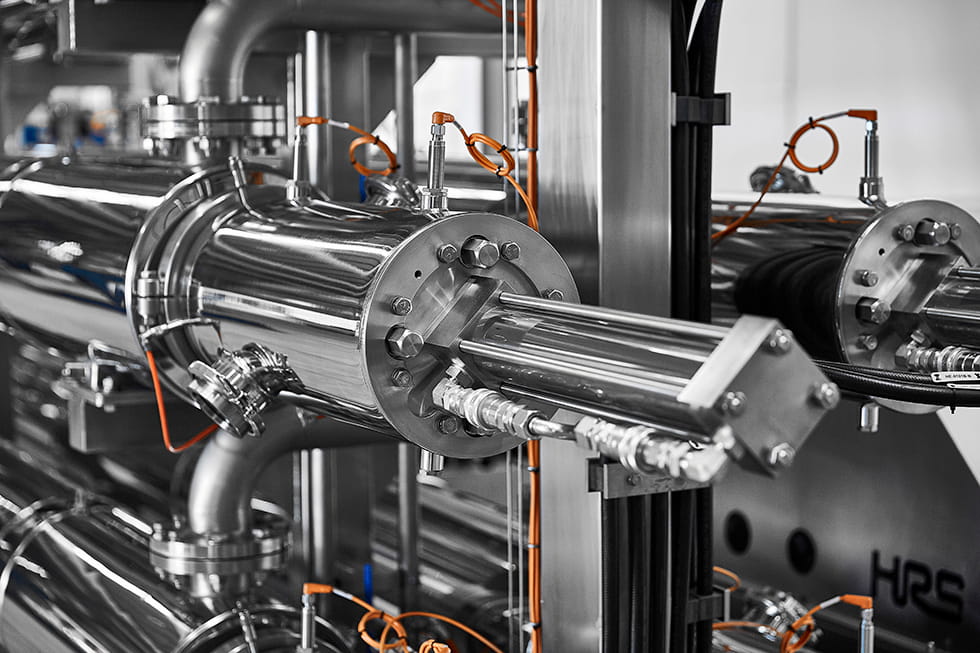

Tubular heat exchangers consist of different combinations of tubes within tubes and come in different forms, including those with corrugated tubes. Corrugated tubes increase product turbulence compared to smooth tubes (which are more common). This prevents fouling and improves operating efficiency. Corrugated tube heat exchangers are ideal for products with medium viscosity or containing small particles in suspension, such as creams, sauces, etc. As materials become more viscous in nature, tube-in-tube or annular space designs may be a better fit.

%20are%20designed%20for%20more%20viscous%20materials.jpg)

For high fouling materials and viscous fluids—or those containing large particles such as fruit pieces—scraped surface heat exchangers (SSHEs) may be the best choice. Different designs, such as reciprocating or rotary versions, provide options in terms of gentle handling (to maintain product integrity for creams or thick sauces, for example) or thorough mixing (for mechanically deboned meat, jams, etc.) while maximizing operating efficiency and uptime.

3. Will the heat exchanger cope with my product(s)?

Product features such as viscosity, solids content and texture will all affect thermal and physical behavior in a heat exchanger. Suppliers need to understand product properties, as well as factors such as the required flow rate and temperature change, in order to supply the correct solution. While there may be plenty of existing data and experience for common materials such as milk, other products such as complex sauces or meat products will need specific analysis and solutions.

A failure to understand the product can result in ineffective treatment that could affect product safety, product quality, economic returns or usability of the supplied equipment.

4. How will you design the heat exchangers?

Does the supplier use the latest scientific information on energy and heat transfer, or is it relying on papers and data that are out of date? While the heat exchanger needs to perform correctly, other considerations, such as ease of installation and maintenance, are also important. A reputable manufacturer will also be able to offer expert insights into the latest technological advancements that could benefit users’ systems processes and operational costs.

5. How energy efficient is the system?

Energy costs to businesses is important, both from an economic and environmental perspective. Some heat exchanger designs are more energy efficient than others (for example, the use of corrugated tubes improves energy efficiency). In addition, heat exchangers may be able to recover heat from the end of the process and reuse it in a process known as heat regeneration.

Although potential energy cost savings need to be offset against the capital and running costs of the heat exchanger, the heat exchanger supplier should be able to provide details of the efficiency of all aspects of their equipment and offer heat regeneration where it is desirable.

6. Will you supply a complete system?

Some suppliers will only supply components, leaving the user or a third-party engineering contractor to combine the heat exchanger and control systems with the necessary ancillaries, such as pipework, pumps, holding tanks, etc. Some systems will use a combination of two or more heat exchangers—for example, a simpler system to pre-cool or pre-heat the bulk of the product and then a more specialist system to perform the main process.

If the heat exchanger supplier proposes a complete “plug and play” solution, it is likely the various components will work together and the system will perform as expected. This will also provide a single point of contact for any maintenance or warranty queries.

7. Do you offer bespoke solutions?

Different materials have different handling requirements and there is no “one size fits all” solution in terms of heat exchangers. That is why manufacturers produce a range of tubular heat exchangers, from simple multi-tube designs to scraped surface designs that are capable of dealing with high-fouling materials while maintaining product integrity.

However, some suppliers will go further, allowing users to specify particular brands of components or controllers—for example, to comply with existing factory maintenance contracts or traceability systems.

8. How easily will the system integrate with my current operation?

Following on from the question above, operation and maintenance will vary according to the type of heat exchanger chosen, its design and the environment in which it is used. Involving engineering and hygiene teams at an early stage can ensure the new heat exchanger system is fully integrated with the rest of the facility.

For example, how complicated is it to access key components and what are the costs of routine spare parts such as seals and gaskets? For double and triple tube heat exchangers, is it possible to remove individual tubes without dismantling the entire unit, and is it possible to service parts of the unit without shutting down the whole process? These factors will have a key impact on how much the heat exchanger costs to service, both financially and in regard to the time and resources required.

9. What after-sales support do you offer?

Does the potential supplier offer features such as extended maintenance and servicing? Would it be possible to take advantage of any future upgrades, such as improvements in tube design? It may not be essential to deal with a company that is based locally, but it is a good idea to investigate how well they deal with other clients in similar circumstances and what their support offering looks like.

Also, what role does the heat exchanger manufacturer play in installation and commissioning? What training is provided for operators and engineering staff? Is equipment fitted with remote access and monitoring systems so the manufacturer can access key information and metrics and, when necessary, log on and discover any potential issues and quickly identify their resolution?

If a potential supplier becomes defensive or is unable to answer any of the above questions, it may be time to look for another supplier. However, if a company is happy to engage and is open and transparent when responding to questions, this bodes well for a good working relationship. Hopefully this relationship will lead to the supply of a heat exchanger that will meet specifications and work reliably for many years to come.