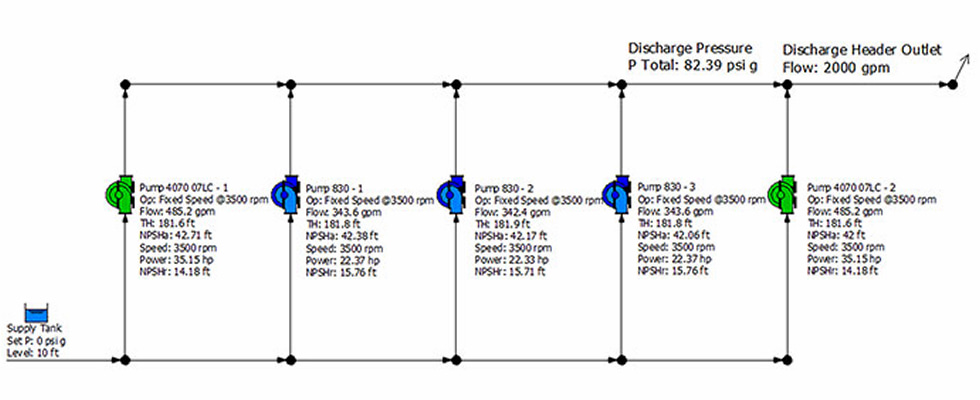

One common misconception I hear is that a pump is rated for a certain flow rate and the pump is bad if it does not deliver. While this may be true when you are discharging to a spillway and there is little resistance, most pumping systems are much more complicated. I was recently dealing with a situation where multiple pumps in parallel and the operators and engineers were confused as to why they were not getting the flow or pressure they thought they should. In fact, they were only operating with one of the two cooling towers available due to the lack of flow. The system had been expanded many times, and they were considering expensive repairs to the pump manifold that would total more than $100,000. Since the system had been in operation for many years, there were not many places to collect data. There was a pressure gauge on the pump manifold. It was known that the cooling tower would overflow at 2,200 gallons per minute (gpm), so a flow rate of around 2,000 gpm was assumed. While we looked at modeling the entire system, the crux of the problem can be seen in just the model of the pump manifold. There were two larger pumps on the ends (Pump 4070) with three slightly smaller pumps (Pump 830) in the middle (Image 1). The pumps were operating at just over 82 pounds per square inch (psi).

Image 1. Pump manifold under normal operation. (Images courtesy of the author)

Image 1. Pump manifold under normal operation. (Images courtesy of the author) Image 2. Pump manifold with one pump shutdown

Image 2. Pump manifold with one pump shutdown Image 3. Pump 830 under normal operation.

Image 3. Pump 830 under normal operation. Image 4. Pump 830 with one pump shut down

Image 4. Pump 830 with one pump shut down