HI Pump FAQs

03/28/2018

Q. How can I determine if my pumping system is a good candidate for improved energy efficiency?

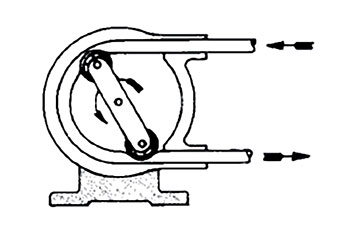

A. Below is a list of common indicators that may signify a pumping system contains inefficiencies: Figure 3.1.4.2. Flexible tube pump (peristaltic) (Images courtesy of HI)

Figure 3.1.4.2. Flexible tube pump (peristaltic) (Images courtesy of HI)- highly throttled flow control valves

- bypass line (recirculation) flow regulation

- batch type processes in which one or more pumps operate continuously

- frequent on/off cycling of a pump in a continuous process

- presence of cavitation noise

- a parallel pump system with the same number of pumps always operating

- a pump system that has undergone a change in function without modification

- a pump system with no means of measuring flow, pressure or power

- a pump system with frequent failures and high maintenance costs

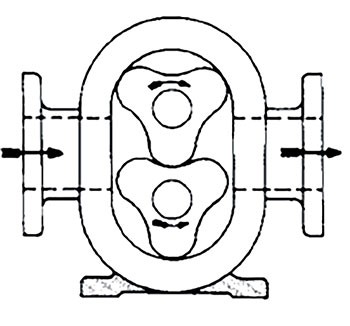

Figure 3.1.5b. Three-lobe pump

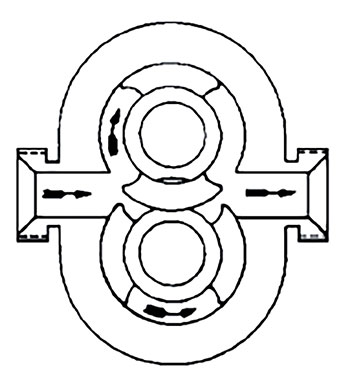

Figure 3.1.5b. Three-lobe pump Figure 3.1.7. Circumferential piston pump

Figure 3.1.7. Circumferential piston pumpQ. What are some common positive displacement pumps uses in the wastewater industry?

A. Positive displacement pumps provide a certain volume of liquid with every revolution of the shaft that is relatively independent of the differential pressure, which makes them different from rotodynamic or centrifugal pumps. Water/wastewater treatment is the second largest positive displacement pump market. There are many kinds of positive displacement pumps used in the wastewater industry, but images for four types are provided. Figure 3.1.8.1. Single-screw pump (progressing cavity)

Figure 3.1.8.1. Single-screw pump (progressing cavity)

See other HI Pump FAQs articles here.