It has long been recognized that rubber expansion joints (REJs) provide critical design functions that impact the reliability of the entire piping system. This has led some industry professionals to an overly conservative calendar-based replacement program and others to a somewhat reckless approach based on running equipment to failure. Maximizing an expansion joint's functional benefits while minimizing its inherent risk has always been a goal for the industry. Until recently, end users have addressed this concern by using performance replacement REJs along with best practices for maintenance, reliability and operations (MRO). These strategies should not be minimized. However, significant advancements have been made using a failure modes and effects analysis (FMEA) program and improved technologies related to the detection of failure modes. Specifically, synthetic aperture radar (SAR) has shown significant promise in improving nondestructive inspection of the inner construction of REJs. Combining performance replacement REJs with traditional and advanced inspection methods in an FMEA program can help end users to improve the management of REJs in piping systems in order to maximize plant reliability and efficiency. The critical design functions of REJs include their ability to accept all directional movements and to reduce noise and vibration in the piping system. These pieces of equipment are also designed to have a cycle life in the tens of millions of cycles, compensate for misalignments, provide access to piping and equipment, and relieve pipe and anchor stresses. However, the characteristics of rubber lead to degradation over time, which is accelerated by stress and temperature. These conditions are common in power and process systems. Unchecked degradation can lead to a catastrophic failure that could cause a plant shutdown. However, rigid piping systems designed without REJs or a means of handling the thermal growth and other external movements can lead to the same catastrophic consequences despite inspection or maintenance frequency.

Image 1. Inspection of REJ body blister as a failure mode (Image and graphic courtesy of FSA)

Image 1. Inspection of REJ body blister as a failure mode (Image and graphic courtesy of FSA)Improved Technologies

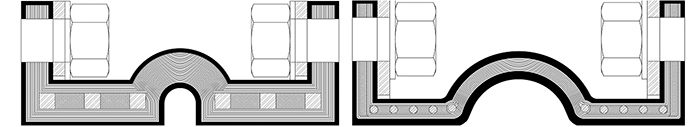

Improved materials and manufacturing technologies have led to increased design function and have minimized the inherent risk of the REJ. For example, fabric reinforcement, which was traditionally square-woven cotton or polyester weave, can be upgraded to tire cord. Square-woven implies that the fabric strands are perpendicular to each other and have approximately the same strength in each direction. If a greater strength is needed in only one direction, the design requires an increase in the overall number of plies, which increases body thickness, reduces movement capability and increases overall stiffness. A thicker body also reduces the projected flange sealing area and can increase the risk of REJ flange leakage. The use of tire cord allows the bias angle to be changed to increase the strength in one direction over the other. This is significant because, depending on the application, the static forces in an REJ can be considerably different in the axial versus the radial direction. Tire cord also ensures a superior rubber-to-fabric bond because it is coated with a specially formulated adhesive—resorcinol formaldehyde latex (RFL). The tire industry developed the RFL coating to improve adhesion and prevent ply separation and delamination. The combination of an improved elastomeric bond as well as an optimal number and angle of plies creates a homogeneous composite with consistent and predictable engineering capabilities. Greater flexibility in today's REJs minimizes their own internal stresses as well as external stresses to the piping system. The reduction of internal stress minimizes the effects of aging and leads to a longer service life. System stress reduction is achieved when the expansion joint accepts thermal movements, relieving thermal stresses that can quickly exceed allowable pipe stresses. Other advanced materials have made it possible for REJs to be used with a wider range of chemically abrasive and erosive mediums under higher system temperatures and pressures. Building the REJ to exact field dimensions is another example of improving performance and reducing risk. Over time, piping and equipment settle and offset at different rates. For example, a large diameter condenser REJ may develop nonparallel flanges and a lateral offset in excess of 2 inches over the course of its useful life. While the condenser and piping system as a whole have many years of use left, the problem becomes how to bridge this offset with a replacement REJ. When replacing a valve and REJ, it is often cost-prohibitive to realign the piping or equipment. It is also unrealistic to order a replacement valve with varying overall lengths and built-in lateral offsets. It is relatively inexpensive for a qualified REJ manufacturer to incorporate these field dimensions into a performance replacement. In a not-so-unusual case, the installation crew spent a great deal of time and effort forcing a nonperformance REJ into an offset and misaligned location. After an exhaustive installation process, the nonperformance replacement REJ had a substantially reduced life because of permanent stresses imposed on it. In some cases, the actual field dimensions exceed the allowable movement capabilities of the joint, resulting in rapid aging. Building an REJ to exact field dimensions ensures that the full allowable movement capability and useful life are maintained while also minimizing installation and maintenance costs. Performance replacement REJs also offer ease of installation and greater installation tolerances because of their improved flexibility, and they provide zero leakage because of optimal body thickness and improved flange design. Figure 1. Cross sections of bi-directional REJ (left) vs. unidirectional REJ (right)

Figure 1. Cross sections of bi-directional REJ (left) vs. unidirectional REJ (right)