Adecade-old, 1,000-megawatt (MW) combined cycle power plant in the Middle East called an equipment repair and engineering company to conduct a pump health audit. Given the age of the plant and the fact that none of the pumps had undergone a major overhaul, plant personnel asked the engineering firm to determine which pumps should be pulled for repair at the next scheduled outage. The equipment consisted of six condensate extraction pumps and six boiler feed pumps. Leaving the production process undisturbed, the field pump health evaluation team conducted a non-invasive pump study. Flow, pressure, vibration, power consumption, temperature and other data were collected for all the pumps in various regimes of operation. A team of engineers analyzed and compared the results of the measurements to the original design parameters. The study’s conclusions and engineering recommendations were published. The audit revealed that the pumps were in good working order. The team used a pump wellness assessment for hydraulic, mechanical and electrical criteria, and only one pump triggered a “caution” indicator. The following represents the assessment’s results:

- Condensate extraction pumps

- Operating parameters for four pumps were acceptable.

- Monthly vibration trending observations were recommended for two pumps.

- Boiler feed pumps

- Four pumps were found to be in good working order.

- One pump showed in its hydraulic parameters signs of mechanical wear but was deemed operationally worthy for another 18 to 24 months.

- One pump was incorrectly operated with a control valve opened at only 38 percent.

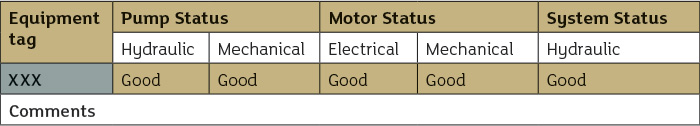

Table 1. Pump health report table head (Courtesy of Hydro Inc.).

Table 1. Pump health report table head (Courtesy of Hydro Inc.).