Problem

Fluff pulp, a material often found in the absorbent core of products like diapers and towels, may be soft—but producing it can be hard. In fact, the absorbent, soft characteristics that make fluff pulp ideal for those types of applications are the same ones that present challenges in the production process. Marble-sized “clinkers” made of ash accumulated during pulp production are known to create clunky masses that can impact flow control. Over time, they can accumulate and form blockages and leaks, especially if the industrial processing pump is not fit to withstand this costly industry challenge.

That is what happened to a leading fluff pulp producer that experienced constant disruptions when their pump failed to pass these clumps during green liquor underflow processing. This was causing pump leakages, and the manufacturer was considering costly solutions like coating the casings with a ceramic material. As frustrations and challenges mounted, they also experienced leakages caused by a buildup of solids in the pump that were sitting in the suction nozzle and rotating with the impeller, which quickly wore out the nozzle. The only way to ensure these malfunctions were less frequent was to regularly shut down the pumps to be backflushed and sometimes disassembled to clean out the clinkers, leading to even more downtime in the long run.

So, what was the issue at the heart of all these malfunctions? The pumps they were utilizing were not durable enough for this application and were ill-equipped to manage the transfer of low volumes (50 to 80 gallons per minute [gpm]) of settled clinkers from the clarifier to the green liquor dregs filter while avoiding buildup. Unfortunately, this is a critical chemical recovery process for the manufacture of fluff pulp, as ash from the burning of black liquor is processed into white liquor to be used in the kraft digestion process of wood pulp.

Solution

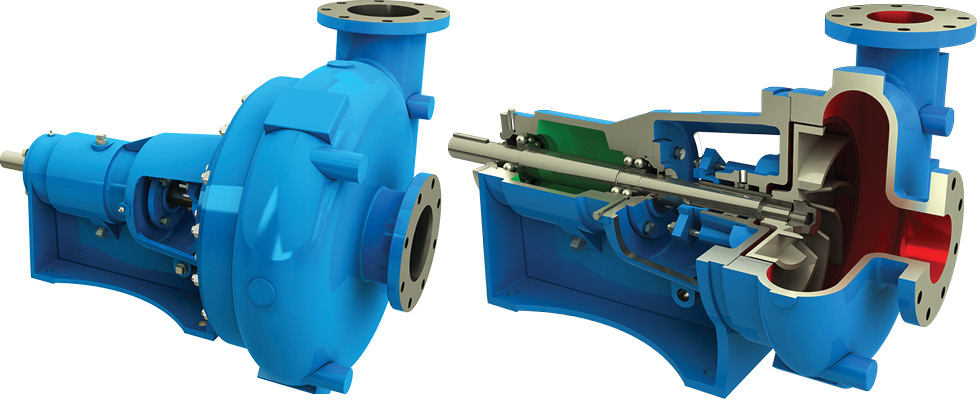

The company needed a pulp and paper industry solution that was built with these unique challenges in mind, and the engineers found a pump that addressed their process requirements in a horizontal hydro-solids pump. Utilizing a horizontal pump built to process hydro-solids, like clinkers, quickly solved the plant’s most pressing issues, including:

Blockages: A recessed impeller design is able to pass large particle solids up to 10 inches in diameter and fibrous/stringy materials easily through the discharge.

Leakages: The 2-inch suction nozzle on a hydro-solid pump does not need a suction reducer, eliminating the risk of leakages caused by clogging in the pipe.

Engineers are also able to fit these kinds of pumps onto the existing polyshield foundations of other standard pump solutions, eliminating the need for major infrastructure adjustments to account for a change in hardware.

Due to the pumps’ design for processing fibrous or stringy materials that are prone to buildup, they are often also trusted by industries including waste treatment, food processing, primary metals and mining. The ability to withstand these conditions is due to a strategic design that includes a nonclog impeller, back pull-out design and extra thick casing and impeller design.