Plus the Top 4 anomalies to look for when performing a field inspection.

Garlock Sealing Technologies

12/18/2018

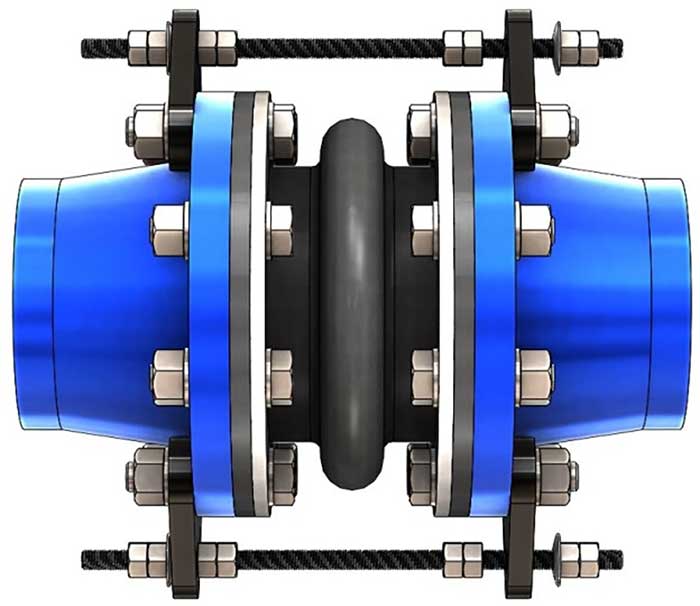

Image 1. Control unit installed (Images courtesy of the author)

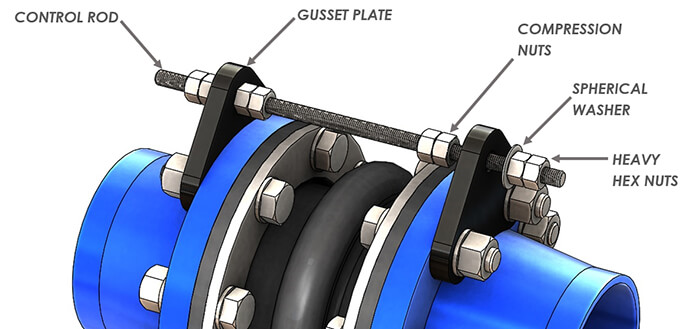

Image 1. Control unit installed (Images courtesy of the author) Image 2. Typical control rod assembly components

Image 2. Typical control rod assembly componentsMethods to the Madness

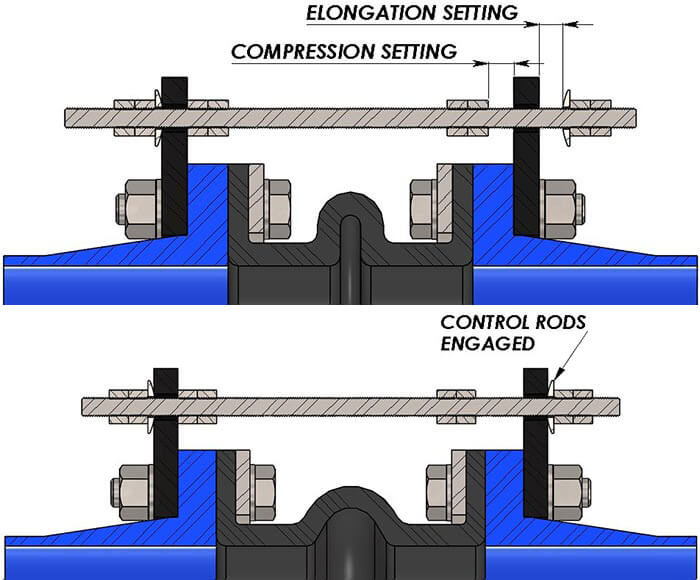

A common misconception about control units is that they are designed to support the weight of pipe members or act as a substitute for adequate mounting. They are not. The sole purpose of a control unit is to allow the expansion joint to move freely within a specific range of movement while preventing the joint from being overstretched from pressure thrust forces. Image 3. Effects of pressure thrust

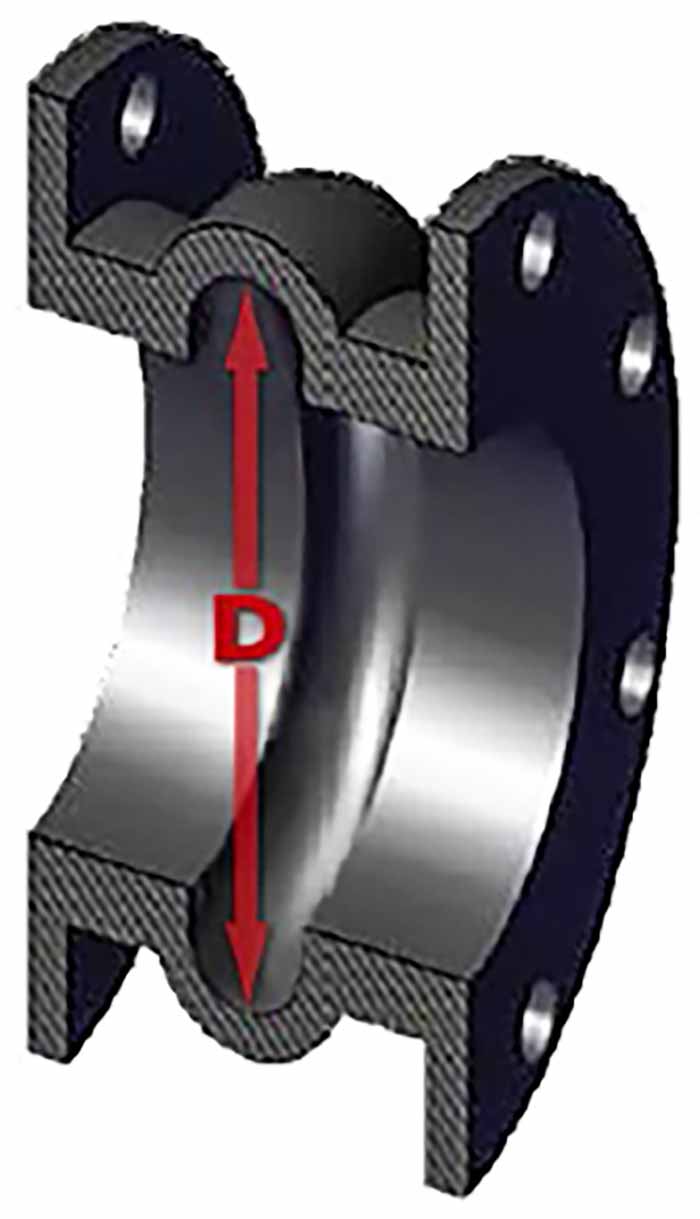

Image 3. Effects of pressure thrust Image 4. Arch diameter “D”

Image 4. Arch diameter “D” These design limitations based around yield stress are the reasons why some control units made from lower yield strength stainless steel contain thicker components or more rods per set than the standard carbon steel control units.

These design limitations based around yield stress are the reasons why some control units made from lower yield strength stainless steel contain thicker components or more rods per set than the standard carbon steel control units.

Installation & Inspection

For a control unit assembly to be effective, rod positioning and elongation settings are critical during installation. Each control rod should be evenly spaced around the flange to best distribute the load. Elongation settings (see Image 5) are often overlooked, yet are a vital factor to ensure the control units fulfill their intended use. Every expansion joint comes with movement ratings based on arch size, configuration and number. These movement design ratings of the expansion joint are critical pieces of information that are absolutely required during the installation of control units. The general rule of thumb is the gap between the gusset plate and the nut should be adjusted to match the joint’s elongation rating. Having this information at hand during installation is great, but what about the existing control units currently in operation? Visual inspections of these components are a basic task that goes a long way toward extending the life of the joint. Here are the top 4 anomalies to look for when performing a field inspection: Image 5. Measuring elongation setting

Image 5. Measuring elongation setting Image 6. Locked out control rod

Image 6. Locked out control rod Image 7. Control rod interference

Image 7. Control rod interference Image 8. Gusset plate exceeding yield

Image 8. Gusset plate exceeding yield