Addressing the tenth component of a general scope document

William Livoti

Identify and agree on materials and pricing

Addressing the eighth component of a general scope document

Addressing the eighth component of a general scope document

Addressing the seventh component of a general scope document

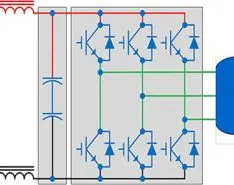

How electronic speed control drives, adjustable frequency drives, magnetic drives and steam turbine drives work to achieve true variable speed control.

Addressing the sixth component of a general scope document

Addressing the fifth component of a general scope document

Addressing the third component of a GSD