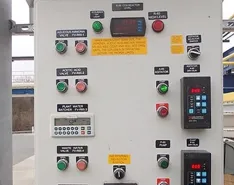

De-energized and energized motor testing are techniques used to spark a VFD’s performance.

Motors

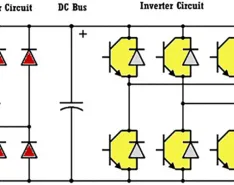

Motors are the most common source of power used by pumping systems. This technology is heavily regulated. Pumps by themselves are not variable speed, an option that many systems need to operate with peaks and ebbs during the run cycle, such as power generation. The addition of a variable frequency drive (VFD) gives it that capability.

Learn how motor circuit analysis tests can be used to identify developing issues.

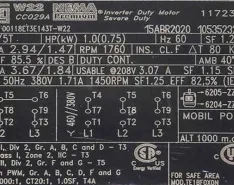

Learn the basics of a nameplate on a three-phase motor.

Learn what motor circuit analysis tests for and identifies.

With today’s advancements in technology, users benefit from smaller components.

Nick Grewal of ePropelled joins the Pumps & Systems podcast to talk electric motors.

Power sensors can positively affect efficiency and contribute to energy savings.

Actionable steps you can take to raise your pumping standards while lowering costs.

Review a comparison of submersible and immersible motor types.

Consider several factors when choosing and implementing sensors for your monitoring program.