What is the difference between a centrifugal and rotary pump?

Centrifugal Pumps

Mitigating water hammer or surge is possible when taking the proper precautions.

Guest columnist Michael Key on how implications of reliability extend beyond just the loss of production while the pump is out of service.

Sliding vane pumps offer a versatile processing option for low-viscosity liquids.

Hydraulic Institute provides the basics on the most common pumps.

Learn how centrifugal pumps, positive displacement pumps and three-screw pumps perform in these cases.

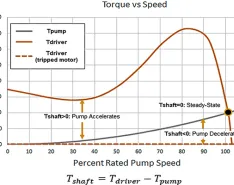

How to achieve smooth and trouble-free operation.

Turbo Lab's Greg Gammon, director of global & corporate partnerships, gives pump industry updates.