Learn which heating method is best for your equipment.

Bearings

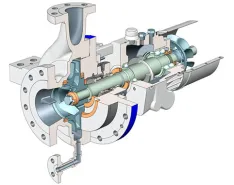

Bearings are small parts of pump systems that play a critical role. They bear the load of the pump, allowing rotation. They must be properly lubricated and temperatures monitored to prevent failure. These articles explain the causes of bearing failure and how to prevent them - thus protecting overall system life.

Consider additional options outside of the bearing housing to improve reliability and reduce operating costs.

The proper grease should be chosen based on factors such as moisture, bearing load, speed, temperature and shaft orientation.

Choice should be based on load, thrust, lubrication and other specific application needs.

Bernd Fischer, Group CEO of Technymon GBT, says demand for bearings is strong in North America and India.

Ryan Ossmann, repair operations manager at Jenkins Electric joins the podcast to talk bearings.

Basic training for selecting, installing and maintaining bearings.

Hydraulic Institute answers question on best method to see if your bearing is failing

Installation techniques and tips for choosing the best material grade.

Bearing seals and isolators can eliminate leaks and contaminants

These bearings use sliding motion and a thin film of oil to provide theoretically infinite life.

Quantifying the benefits of modifications.

Calculate and optimize clearance to lower vibration and running noise.

Find out which bearings are good candidates for this maintenance strategy.

Learn the ins and outs of these rotating machinery components.

Seal failure is often a symptom of an underlying problem within the pump.

New technology can decrease heat and skidding.

Look out for these common pitfalls, and don’t assume that a lubrication leak means a seal failure.

End users can request a prototype sample to test the thermoplastic’s suitability in a given application.

Externally pressurized porous gas bearings are being applied in seal applications for rotating equipment.

Lower coupling restoring forces can increase bearing and seal life.