Reliability is the biggest factor, but power, grids and the plant must also be considered.

Motors

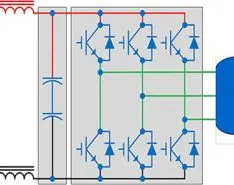

Motors are the most common source of power used by pumping systems. This technology is heavily regulated. Pumps by themselves are not variable speed, an option that many systems need to operate with peaks and ebbs during the run cycle, such as power generation. The addition of a variable frequency drive (VFD) gives it that capability.

A regular maintenance schedule can help users achieve the benefits.

Learn how to implement this technology to help with maintenance and energy costs.

Upgrading instead of replacing can be a practical solution to improve motor reliability.

How to assess the motor system and evaluate components that are under par.

Consider pump selection and running time to reap the most benefits of the overall system.

Use conventional and alternative methods to undertake critical practice of heat management.

Learn what is really behind the horsepower rating on motors.

Users need to ensure that their drives are efficient, reliable and—most importantly—safe.

Knowing revolutions per minute is critical to adjusting power to match system requirements.

Choice should be based on load, thrust, lubrication and other specific application needs.

Permanent magnet motor technology gives users an option beyond surface and submersible choices.

Distorted waveforms can cause wasteful heat, more frequent equipment failure and added costs from increased power usage.

Variable mixing can provide a homogeneous process volume, consistent temperature and improved biological contact.

Artificial intelligence and machine learning were hot topics at the show

EASA specialist says artificial intelligence and machine learning are here to stay.

Engineers are eschewing large motors for less centralized systems.

How electronic speed control drives, adjustable frequency drives, magnetic drives and steam turbine drives work to achieve true variable speed control.

VFDs can extend life by reducing wear on equipment and motors.

Consider these methods to help protect systems from high-frequency current damage.

Understand these concepts before starting squirrel cage induction motors.

Harmful common mode shaft voltages can damage motor bearings and cause premature machine failure.