This hot topic is one of the most popular searches on Pumps & Systems’ website.

Pumps

In the process industries—water, wastewater, oil and gas, food and beverage, chemical processing, mining, building services, pulp and paper—pumps are ubiquitous. The pumps used in those industries vary widely and each requires expert handling. These articles provide information on selecting the right pump for the application, as well as testing and troubleshooting, installation and maintenance on those pumps.

Newtonian and non-Newtonian fluids react differently to temperature, so they require different equipment.

These pumps can handle both system and liquid changes.

Acceleration transducers (accelerometers) are typically used to measure vibration on stationary components.

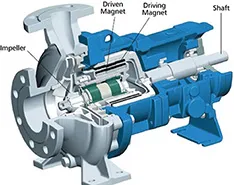

The design does not use a dynamic shaft seal as a primary containment device.

Setting alarm limits and adjusting the alarm structure will help stave off inadequacies.

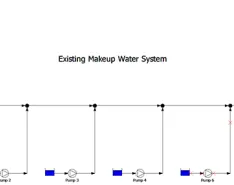

Columnist Ray Hardee walks through an example of a mill's makeup water system and how it saved money.

Hear how condition monitoring can be tied to lubrication management

Market reduction of 25 percent, disappearance of lighting rebates are among key differences.

Distributors and users will be directly impacted by the upcoming Department of Energy requirements.

Magnetic couplings and wet rotors are key features contributing to the technology.

Columnist Jim Elsey gives more examples of problems pumps might face and how a good salesperson would handle them.

Industry veteran explains what worries him today, advice for young workers

Dissolved chemicals in the water are probably not a good sign.

This case study focuses on optimizing productivity and delivering the right level of system performance.

Additional tips to help keep gremlins away from your system.

The marketing professional also shares tips for getting people to come.

Hold on to your curiosity as you grow older, and learn to embrace change.

Tsurumi’s Glenn Wieczorek says these two components are what drives the 40-year-old company.