IIoT and data science make it easier to analyze and improve pump system performance.

August 2020

Learn which heating method is best for your equipment.

What are the best practices for sealing equipment with high thermal expansion?

PSAPs meet rigorous required criteria to assess a pump system.

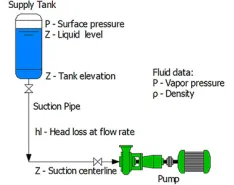

There are two ways of expressing NPSH relative to a centrifugal pumping system.

Simplify flow meter setup and get accurate data.

The initial purchase and installation cost of a new pumping system is a small portion of the life cycle cost of the pump.

The potential for energy savings and water use ratio (WUR) reduction can be identified swiftly if focus is placed on pump components such as mechanical seals.

Build a solid condition-based reliability program with this proven best practice.

Use these methods to correctly trim an impeller or underfile discharge vanes.

There are four classes of monitoring methods for LoRaWan use.

Some causes for these forced vibrations are misalignment of the pump and driver shaft.

This often-ambiguous calculation is critical to making data-driven fleet decisions.

Standards help, but do not aid in the implementation process.

This often-ambiguous calculation is critical to making data-driven fleet decisions.

Automated meshing facilitates simulations for optimizing systems.

Learn how this alternative to metallics can boost your system.

There are four classes of monitoring methods for LoRaWan use.

Consider additional options outside of the bearing housing to improve reliability and reduce operating costs.