Many coatings support the extreme environment of the oil and gas industry

Pumps

In the process industries—water, wastewater, oil and gas, food and beverage, chemical processing, mining, building services, pulp and paper—pumps are ubiquitous. The pumps used in those industries vary widely and each requires expert handling. These articles provide information on selecting the right pump for the application, as well as testing and troubleshooting, installation and maintenance on those pumps.

Protecting these difficult-to-remove workhorses is critical for prolonged life.

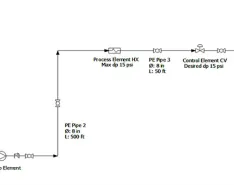

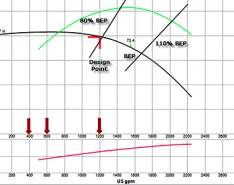

The second part of Ray Hardee's series on front end engineering design

How to identify safety hazards and implement training to avoid plant downtime.

Repetitive problems occurred due to high vibration on pumps for light naphtha service.

A three-screw pump can provide smooth, pulsation-free flow.

Preventing unscheduled shutdowns and delay

Here’s an update on what happened recently, and what to pay attention to.

Parts must meet certain standards in sanitary food or pharmaceutical pumping.

Evaluation leads to a redesign and improved assembly approach, correcting commissioning issues at an alumina processing plant.

Flexible pump design with aftermarket support are keys to success.

Consider viscosity, flow rates and required accuracy when making a selection.

Many uncertainties, along with general optimism, highlighted the spring annual conference in Tucson, Arizona.

The effect front-end engineering design can have on the system

The differences in vibrations that can occur within the pump

Review pump types and pick proper construction materials.

The reliability and efficiency of components of hydronic HVAC systems can impact the bottom line.

The labor shortage could cause these to run together in newer buildings.