Advanced technologies optimize operations.

Instrumentation/Controls

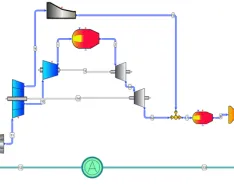

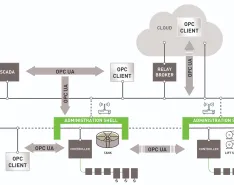

Pump systems have long been operated through monitors and controls. In recent years, growth of the industrial internet of things (IIoT) has exponentially increased the way sites can collect, store and analyze data to improve operations. This is the fastest growing industry sector.

Leverage predictive maintenance to avoid costly downtime.

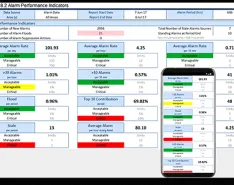

Remote alarm notification software helps fuel increased efficiencies.

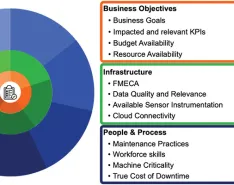

How to best assess if a company is ready to implement predictive maintenance.

In the rapidly evolving landscape of industrial maintenance, artificial intelligence (AI) stands out as a beacon of potential.

Efficiently deploying safety instrumentation at wellhead pumps.

How ESA can help ESPs run better and longer.

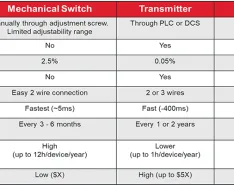

Choosing the correct pressure switch is critical to ensuring safety and efficiency.

Real-time alarms and historical data drive better processes.

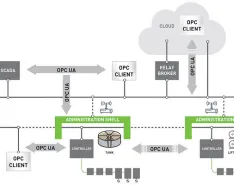

OPC-UA and remote alarm notification software help in this process.

A closer look at switching technologies and their uses.

How these devices can reduce maintenance hours, enhance operations and cut costs.

Harness the power of data analytics to predict machine faults and mitigate them

It is critical to properly follow specifications when establishing a performance test field.

Maintaining pumps in these operations can be a challenging task.

Electromagnetic flow meters were an accurate alternative.

Mitigate the growing pains that can come with updating processes.

How complex should a user’s control panel really be?

Understand sensors and their uses in industry applications.

Pump telematics can reduce costs, labor requirements and waste.

OPC-UA and remote alarm notification software help in this process.