See what happens when bearings are overloaded.

August 2021

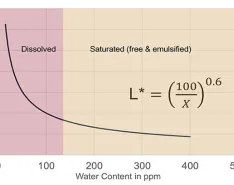

Maintaining a low level of moisture and humidity in pump bearing housings is critical.

Viscosity will affect positive displacement and rotodynamic pumps differently.

Why users need to understand system head curves and their benefits in proper pump selection.

Pump engineers are familiar with the performance curve of a centrifugal pump.

Answer these 4 questions when specifying a pumping system for a dredge.

Noncontact seals can help provide maintenance and protect bearing life.

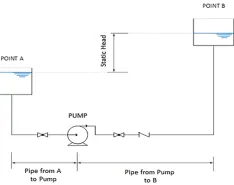

Learn safe assumptions when calculating the total head of a pump and how to deal with an oversized or undersized pump.

A look into the testing considerations when selecting a pump for hydronic applications.

Learn what factors make this technology popular in today’s environment.

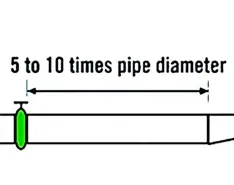

The more gradually a system can slow its flow, the better a pressure surge is mitigated.

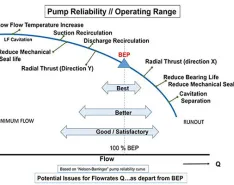

In part 2 of this series, Elsey discusses best efficiency point.

The newest generation of split seals offers cost savings, self-alignment and eliminates need for equipment disassembly.

How to use the National Lubricating Grease Institute’s high-performance multiuse grease specification for pump maintenance.

Tips and tricks for maintaining safety in any work environment.

How to ensure your centrifugal pump is operating efficiently.

Improve centrifugal pump reliability by optimizing bearing clearance.

This month, we will look at a new project from its inception through the design and build stages until the project is turned over to the client.

These motor systems can run at a synchronous speed, providing improved hydraulic performance.

Find out why a system failed and what could be done to prevent repeated failures.