Power plants with boiler feed pumps are finding more efficiency.

June 2019

Engineers are eschewing large motors for less centralized systems.

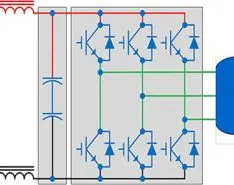

How electronic speed control drives, adjustable frequency drives, magnetic drives and steam turbine drives work to achieve true variable speed control.

Addressing the sixth component of a general scope document

VFDs can extend life by reducing wear on equipment and motors.

Predictive maintenance can provide detailed data and actionable repair instructions.

A hybrid approach can provide specialized evaluation for midtier plants and/or midcritical equipment.

Consider these methods to help protect systems from high-frequency current damage.

Understand these concepts before starting squirrel cage induction motors.

Understand calculations and specifications.

Harmful common mode shaft voltages can damage motor bearings and cause premature machine failure.

Separation can improve delivery time and allow exact replacement.

Rely on touch, sound and sight—and tools that enhance these senses—for equipment longevity.

Hydraulic Institute answers questions on rolling element bearings and grease as a lubricant.

Understand implications involved with using gas film seals in this application.

Condition monitoring helps manage over-lubrication.

Furnace blower motor design transformation was fueled by new end user and government standards.

Understand the pump specific speed to help establish proper tolerance.

Differentiating between misalignment and imbalance is essential to identifying the cause of pump failure.

This technology can help reduce blockages, detect damaged equipment and avoid dry runs, thus reducing motor stress.