Strategies to keep pumps running smoothly and efficiently.

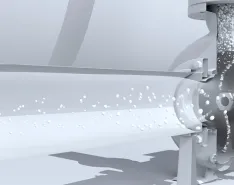

Cavitation

Neglecting to properly calculate NPSH or leave sufficient margin can result in damaging pump cavitation and system failure.

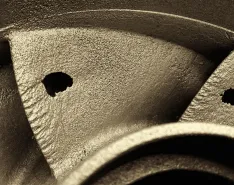

Specific to the pump, cavitation is known for causing reduced performance, noise and erosion damage.

Prevent costly failures by combating cavitation head on.

How to avoid cavitation from the outset.

How operators can use technology to keep their facilities running successfully.

Learn about pump damage, ideal applications and more in this Q&A from SWPA.

Understand cavitation, suction energy, specific gravity and more.

Get to know us as we also share some key articles in the December 2021 issue.

Defining the standard equipment, procedure and policies to the standards of API 610.

White Paper

Understand more about this condition and why its causes are difficult to identify.

Sponsored by

Smart variable speed drives offer an efficient and cost-effective method of prevention.

Solutions to avoid cavitation and fatigue due to operational and design issues.

White Paper

Everything you need to minimize maintenance and replacement costs.

Sponsored by

Practical notes and useful guidelines for dealing with these aspects of centrifugal pumps.

Solution measures temperature and vibration to detect failure modes.

There are two ways of expressing NPSH relative to a centrifugal pumping system.

Automated meshing facilitates simulations for optimizing systems.