Identify what types of automation are possible and what level of control and accuracy is needed.

Valves

Valves regulate and control flow and pressure in pumping systems. They also play an important role in site safety. Understanding the types of valves and how they work can help end users select the right valves for their application’s use.

This material is a key component in oil and gas applications.

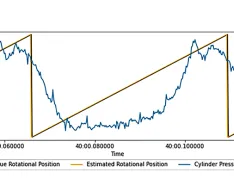

Physics-based and data-driven algorithms make earlier detection of faults possible.

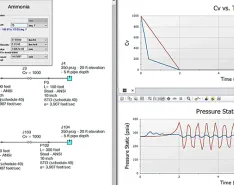

Water hammer analysis software can help improve reliability of systems.

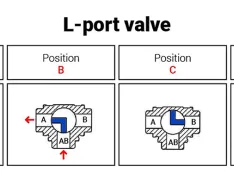

How the correct ball valve can provide flexible flow control.

Steady water pressure is important to daily functioning.

Understand flow control characteristics for valves in your application.

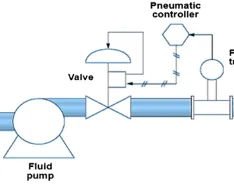

How actuators play a role in stages of flow control.

How these valves compare to other options for an application.

Understand the benefits of guided piston valves in pressure protection systems.

Understanding the advantages and disadvantages of this technology makes it easier to make the right choice.

The application, cost and control system scheme can all play a part in choosing an actuator.

Considerations for valves that are often overlooked or undefined.

A variable speed pump station design will require additional considerations.

Factors such as scaling, orientation and cycle time must be considered to avoid potential issues.

The more gradually a system can slow its flow, the better a pressure surge is mitigated.

Understand how to maintain safety and reliability.

A look at two-piece and three-piece ball valves and total cost of ownership.

Monitoring valves on a regular basis can help avoid problems

The two independent plug seals separate fluids and minimize leakage.

Valves and pumping technology that should be considered to manage stormwater runoff.

Understand features of resilient hinge valves compared to traditional valves.