Avoiding common mode voltage and maintaining bearings can help prevent frequent causes of motor failure.

June 2023

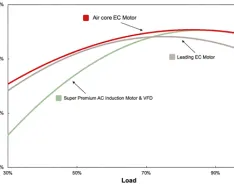

Choosing the right EC motor can aid sustainability efforts.

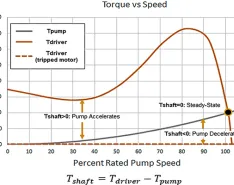

Mitigating water hammer or surge is possible when taking the proper precautions.

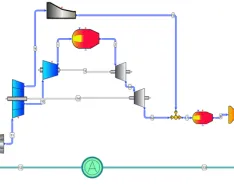

Hydraulic Institute explains differences between these common parts of a boiler feed pump.

Installing and operating IIoT solutions requires careful considerations.

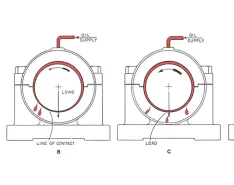

Design, oil viscosity, clearance and functionality are important for proper function.

Understand the role HDSs can play in oil and gas industry applications.

An introduction to two of the most popular motors used in submersible pumps.

Focusing on energy efficiency pays off in the long run.

Direct steam injection is a method to alleviate problems.

Pumps can be prone to various problems that affect their performance and reliability.

Understand sensors and their uses in industry applications.

The paper industry uses constant monitoring of critical motors to prevent failures at startup and reduce safety risks for personnel.

Ensuring actuator health keeps operations running smoothly.

Design, maintenance and installation regulations help make sure these pumps are operating properly.

There is a structured document—a repair standard—in which different levels of repair can be applied.

How advanced signal processing can provide machinery health insights.

The adaptability in variable frequency drives allows for ease of use in several industries.

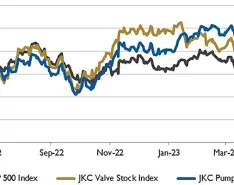

The Jordan Knauff & Company (JKC) Valve Stock Index was up 0.2% over the last 12 months, and the broader S&P 500 index was up 0.3%.

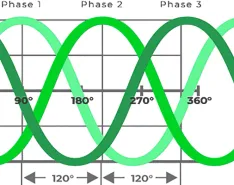

Help extend the duration of your plant’s AC motors.

Pump telematics can reduce costs, labor requirements and waste.