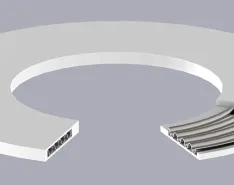

Sealing solutions for nonmetallic piping systems.

Gaskets

Understanding the benefits and common applications of these gaskets.

Shifts toward environmentally friendly solutions will necessitate careful planning.

How reverse engineering technology can enhance reliability and minimize downtime.

Avoid leaking by selecting the right material for the application.

Compare gasket mechanical behavior from subambient to elevated temperatures.

Select the right expansion joint for your coal-fired power station.

Expansion of refinery capacity foreseen to strengthen demand for the component.

Learn why updates are needed for API test standard 607 and stay tuned for more.