Focus on project justification, goals and expectations.

April 2018

Select the right pump early on to prevent later adjustments.

We talked to industry experts about how things have changed since the 2015 oil price crash.

A district with a small staff improves its efficiency with better technology.

It takes careful planning and proactive policies.

Radar level measurement and electronic differential pressure devices provide solutions for drilling sites.

With the right modifications, this technology can handle heat and viscosity variability.

Learn economical ways to deal with production logistics.

Predictive analytics and IIoT can be used to ensure pump technology is operating efficiently and effectively.

Avoid cavitation with calculations and a focus on this aspect of the pumped fluid.

Low torqueing loads, inadequate equipment selection or faulty installation could be to blame.

Operators at wells in North Africa and Canada find an alternative to separators and flaring.

Changes can reduce stress and wear on these critical components.

The best components and algorithms can bring peace of mind.

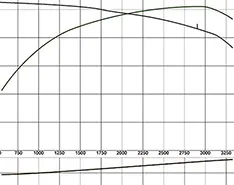

Learn what to expect from centrifugal, reciprocating and rotary pumps.

Early warnings and easy access provide better maintenance options.

By sizing the pipeline correctly, you can reduce both operating costs and the time the pump needs to operate.