Many coatings support the extreme environment of the oil and gas industry

April 2020

Removing sediments and other contaminants prevents buildup and other issues.

Without proper prevention, this sector is in the line of fire for malware attacks.

Understand the operational parameters to make the right choice.

Identify the who, what, when, where and how to select the right equipment.

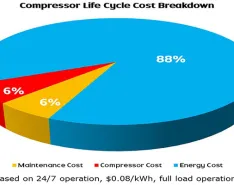

Tips to create and maintain an energy efficient compressed air system.

Tips for selecting seal face materials in harsh conditions.

Protecting these difficult-to-remove workhorses is critical for prolonged life.

Reliability is the biggest factor, but power, grids and the plant must also be considered.

Why end users should use API standards, correct materials and other specifications for the best production outcome.

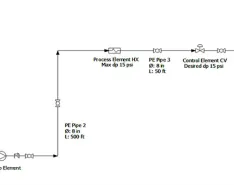

The second part of Ray Hardee's series on front end engineering design

Solution helps avoid effects of contaminates, shaft movement and high-pressure environment.

These bearings are located within a containment shell with no shaft exposed to atmosphere

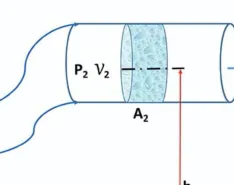

Using Bernoulli's equation to calculate what will happen in a piping system.

Focusing on most common root causes of failure yields reliable results.

How to identify safety hazards and implement training to avoid plant downtime.

How to increase longevity and prevent premature failure.

A liquid-lubricated seal may have no visible leakage.

Repetitive problems occurred due to high vibration on pumps for light naphtha service.

Determine the best calibration procedures for your facility.