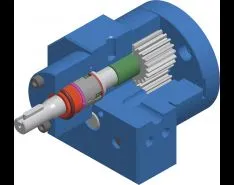

Learning the fundamentals of progressive cavity pump technology and applications.

Progressive Cavity

An efficient solution was needed for a flare knockout drum vessel sump and waste oil storage tank reinjection.

Addressing the eighth component of a general scope document

Whole-system approach improves overall performance.

Potential value of lost viscous product can add up.

Jim Elsey shares 4 more stories from the pump twilight zone

Hydrodynamic principals deliver reliability and can increase polymer savings.

The progressive cavity pump could have run even longer.

Ensure pump startup runs smoothly by avoiding common mistakes.

Overcome low inlet pressure issues and minimize maintenance.

The right oil and gas equipment can simplify the process.

Sanitary requirements are met—even for waste materials—in this New York facility.

Piston pumps and inflatable seals create a system that protects employees and products.

If intermittent problems go unnoticed or cannot be measured and investigated, small issues can become failures.

Stronger is not always better.

One new design can pump up to 80 percent solids and flows up to 450 gpm with a single 4-inch-diameter peristaltic pump.

There are numerous factors to consider to ensure the best performance with this technology.

While PC pumps are ideal for high-viscosity liquids, it can present users with unique challenges.