Follow these tips to lengthen packing life.

Sealing Sense

This practice can ensure safety and reliability of piping systems.

Making use of dual-stage mechanical seal systems.

How to calculate if the bolt material can handle gasket stress.

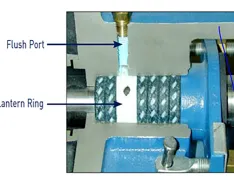

Ensuring stuffing box reliability and controlling the environment mitigate many issues.

The restrained styles restrain, or better manage, the pressure thrust forces within the piping system.

What are the best practices for sealing equipment with high thermal expansion?

The testing characteristics of ductile and brittle bolting materials.

Calculation assumptions can lead to shorter equipment life, more downtime.

Compare the axial and lateral end load conditions for five possible piping designs.

Tips for selecting seal face materials in harsh conditions.

There is a new method to derive gasket design constants for bolted joint design.

Learn why updates are needed for API test standard 607 and stay tuned for more.

Fluid Sealing Association has more than 230 files on mechanical seals and more

One wrong pick could be fatal.

One wrong pick could be fatal.

Learn how different metals react, and how corrosion inhibitors can help avoid downtime.

The Fluid Sealing Association (FSA)’s technical director, Henri Azibert, has retired after leading a long career serving the fluid sealing industry.

Extra energy transmitted can produce larger sealing stress on the gasket.

Strong oxidizers can damage metal, causing pitting or rust and creating possible safety concerns.

A flexible choice can adapt to permanent misalignment, preventing future damage.